Yogurt Packaging

Flexible bag-in-box and pouch packaging provide eco-conscious solutions that keep your yogurt safe and fresh from fill through end-use. With aseptic technology, products are shelf-stable and preservative-free—no refrigeration needed.

Bag-in-Box for Yogurt

With yogurt, quality and freshness are vital for your consumers. Our bag-in-box systems include a wide range of film, fitments, and filling equipment, for a total flexible packaging solution engineered to protect your products from fill through final dispensing. We provide:

- Complete closed-loop systems that protect your product.

- Versatility to deliver your yogurt anywhere you need.

- Solutions that minimize your environmental impact and leave less packaging waste behind.

- Reduced food waste with longer secondary shelf life and maximum product evacuation.

Institutional Bag-in-Box for Yogurt

Safely dispense yogurt with our aseptic-capable, closed-loop systems that minimize opportunities for contamination while in-use and extend freshness upon opening. Our bag-in-box products are designed with fast-paced, foodservice operations in mind with:

- Simple hoses and quick-connect systems for reliable dispensing.

- Easy disconnection with less mess for dispenser cleaning protocols.

- Improved evacuation to maximize profits and minimize waste.

Industrial Bag-in-Box for Yogurt

Use our industrial-sized flexible IBCs, tote liners, and drum liners to safely transport your yogurt in packaging that offers cost savings throughout the supply chain. Our industrial packages facilitate:

- Clean and safe delivery of base material from farms to your production facility.

- Streamlining, demanding less resources to clean and service bulk containers.

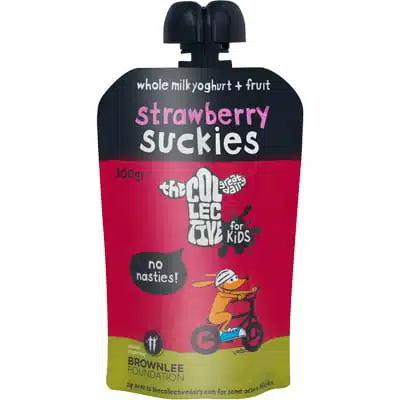

Pouch Packaging for Yogurt

Utilize this highly-convenient and portable package format to offer retail consumers a range of options, including: pouches for use on-the-go; resealable family-size pouches of their favorite yogurt; and trial-size pouches that enable sampling.

- Clean, utensil-free usage in a package that’s easy to “get it all out.”

- Ship smarter with ecommerce-ready flexible pouches.

- Typically lower carbon footprint than heavy rigid alternatives.

- Optimized product-to-package ratio, leaving less waste volume.

Pre-Made Pouches for Yogurt

Our CleanPouch® system helps you streamline your operation by focusing on your product while relying on us to deliver quality pouch packaging. These pre-made spouted pouches are delivered on rail systems, so it’s easy to get your filling operation up and running.

Benefits of CleanPouch® System:

- Various film options, including clear to offer visibility of volume.

- Customizable fitments including choke-resistant cap options.

- Dynamic filling equipment for small and full-scale, automated operations.

Pouch Solutions for Yogurt

If you’re interested in getting started or are already producing pouches using horizontal form-fill-seal (HFFS), count on us for high-quality materials needed for making your pouches:

- Films: Choose from our wide range of options from traditional foil to consumer-preferred transparent. Plus, our RecShield™ pouch film can be recycled with other polyethylene films.

- Fitments: Select from our wide variety of unique and innovative pouch spouts and caps engineered for the rigors of HFFS production.

- Equipment: Use our combined pouch fitments and barrier films in tandem with the top-of-the-line Bossar BMS 4.2 for a complete HFFS pouch packaging solution.