Motor Oil Packaging

Flexible packaging protects your automotive fluids while making them easier to dispense. Our bag-in-box and pouch products reduce hazards, costs, and product waste while increasing efficiency and safety for both consumer retail and automotive business use.

Bag-in-Box for Motor Oil

Dispense the maximum amount of motor oil with our innovative bag-in-box packaging. Our bag-in-box systems include a wide range of film, fitments, and filling equipment for a total flexible packaging solution engineered to protect your products and those who use them, from fill through final dispensing. We provide:

- Complete, secure systems that dispense nearly every drop inside.

- Solutions that reduce your environmental impact and leave less waste behind.

- User-friendly, ergonomic fitments that eliminate splashing and glugging.

- UN-Certified packaging that minimizes costs throughout your supply chain.

Retail Bag-in-Box for Motor Oil

Stand out in crowded retail aisles by offering motor oil in unique, multi-use packaging with benefits like:

- On-tap dispensing with fitments that eliminate glugging and spills.

- SIOC-certified options to open up ecommerce possibilities.

- Improved ergonomics for people of all ages and abilities.

Institutional Bag-in-Box for Motor Oil

Safely dispense nearly every drop of your motor oil with our bag and fitment systems that minimize user error while dispensing quickly and precisely. We design our bag-in-box systems with fast-paced, automotive business operations in mind providing:

- Simple and secure connection systems that attach directly to dispensing equipment.

- Unique fitments that eliminate glugging and spills.

- Improved evacuation to maximize profits and minimize waste.

- Bag and fitment systems designed for both closed-loop and pour-out dispensing.

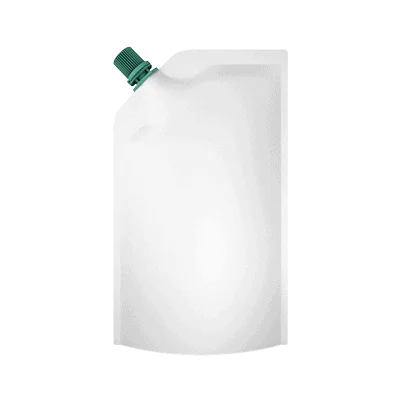

Pouch Packaging for Motor Oil

Increase your market appeal by offering motor oil in this highly-convenient packaging. Flexible spouted pouches are easy to reach into tight, awkward places inside engines, and are perfect for smaller amounts of motor oil for top-off or smaller engines, so consumers can purchase just what they need.

- Ship smarter with compact, flexible, ecommerce-ready pouches.

- Visibility of volume in a package that dispenses with less mess.

- Typically lower carbon footprint than heavy, rigid alternatives.

- Better product-to-package ratio than rigid formats like bottles and jugs.

Pre-Made Pouches for Motor Oil

Our CleanPouch® system helps you streamline your operation by focusing on your product while relying on us to deliver quality pouch packaging. These pre-made spouted pouches are delivered on rail systems, so it’s easy to get your filling operation up and running.

Benefits of the CleanPouch® System:

- Various film options, including transparent to offer product visibility.

- Secure seals and customizable spout and cap options.

- Dynamic filling equipment for startup through full-scale, automated operations.

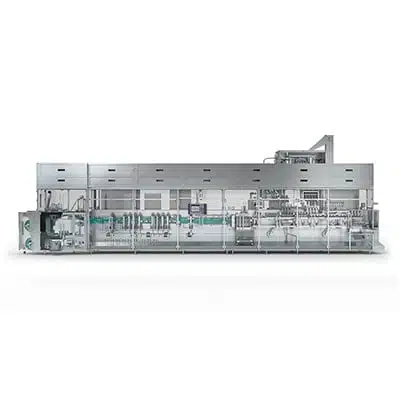

Pouch Solutions for Motor Oil

If you’re interested in getting started or are already producing pouches using horizontal form-fill-seal (HFFS), count on us for the high-quality materials needed for making your pouches:

- Films: Choose from our wide range of options from traditional foil to consumer-preferred transparent. Plus, our RecShield™ pouch film can be recycled with other polyethylene films.

- Fitments: Select from our wide variety of unique and innovative pouch spouts and caps engineered for the rigors of HFFS production.

- Equipment: Use our combined pouch fitments and barrier films in tandem with the top-of-the-line Bossar BMS 4.2 for a complete HFFS pouch packaging solution.