Good Culture Sets an Example for Total Flexible Packaging Solutions

Scholle IPN offers total flexible packaging solutions—that’s a phrase you might have read somewhere on our website as you browsed our innovative films, fitments, and equipment for bag-in-box and pouches.

On their own, implementing just one of our products can drastically reduce waste and improve supply chain efficiency. However, when our films, fitments, and equipment are used together, our customers find exponentially more value and increased sustainability gains.

An Integrated Partnership

Good Culture shares our vision for a turnkey flexible packaging solution. They’re a food company that promotes the health benefits of cultured dairy items like yogurt and cottage cheese. Recently, we worked to redesign Good Culture’s sour cream package to create a new format that harnesses a variety of our cutting-edge technologies.

Good Culture shares our vision for a turnkey flexible packaging solution. They’re a food company that promotes the health benefits of cultured dairy items like yogurt and cottage cheese. Recently, we worked to redesign Good Culture’s sour cream package to create a new format that harnesses a variety of our cutting-edge technologies.

Most sour cream comes in a polypropylene (PP) cup with a pop-off lid, which provides no protection against spoilage once opened, and consumes nearly double the raw materials to manufacture than flexible packaging. Good Culture wanted to find a solution that preserved their product and aligned with their values. They source dairy from regenerative-agricultural farms—like us, they practice building a more circular economy, shifting away from a linear mode of consumption to one that continuously reduces environmental harm and increases efficiency to cut back on waste.

Most sour cream comes in a polypropylene (PP) cup with a pop-off lid, which provides no protection against spoilage once opened, and consumes nearly double the raw materials to manufacture than flexible packaging. Good Culture wanted to find a solution that preserved their product and aligned with their values. They source dairy from regenerative-agricultural farms—like us, they practice building a more circular economy, shifting away from a linear mode of consumption to one that continuously reduces environmental harm and increases efficiency to cut back on waste.

This starts with equipment. We matched Good Culture with a Bossar BMS 1.6, a horizontal form-fill-seal machine that cuts custom-shaped pouches and uses Clean Fill technology, a filling method utilized without the aid of additional sterilization techniques and used for shelf-stable, frozen, and refrigerated items. Their packaging is made of our ClearShield™ film and a FlipCap FTR106 XLR fitment, a single-piece tethered cap that offers ease-of-use for consumers and makes recycling easy because the cap is made as one piece.

This starts with equipment. We matched Good Culture with a Bossar BMS 1.6, a horizontal form-fill-seal machine that cuts custom-shaped pouches and uses Clean Fill technology, a filling method utilized without the aid of additional sterilization techniques and used for shelf-stable, frozen, and refrigerated items. Their packaging is made of our ClearShield™ film and a FlipCap FTR106 XLR fitment, a single-piece tethered cap that offers ease-of-use for consumers and makes recycling easy because the cap is made as one piece.

By utilizing all parts of our total packaging offerings, Good Culture can protect and conserve natural resources and while enjoying sustainability gains in all aspects of their business—from the actual packaging itself to storage, distribution, and better product performance.

Demonstrating Sustainability from Top to Bottom

Scholle IPN always looks for ways to exemplify our values through the tools we engineer and the decisions we make. We recently recommitted to providing our customers a total packaging solution by acquiring Bossar, a leading manufacturer of horizontal form-fill-seal equipment so now, we’re truly a one-stop shop for all things flexible.

Because we provide everything you need to switch to flexible packaging, we can craft a solution that’s exactly tailored to your needs and work with you every step of the way. Good Culture challenged us to find a way to make their sour cream packaging more sustainable—with the decades of technology and resources we’ve developed, we hatched a system that allowed Good Culture to maximize their commitment to responsible manufacturing.

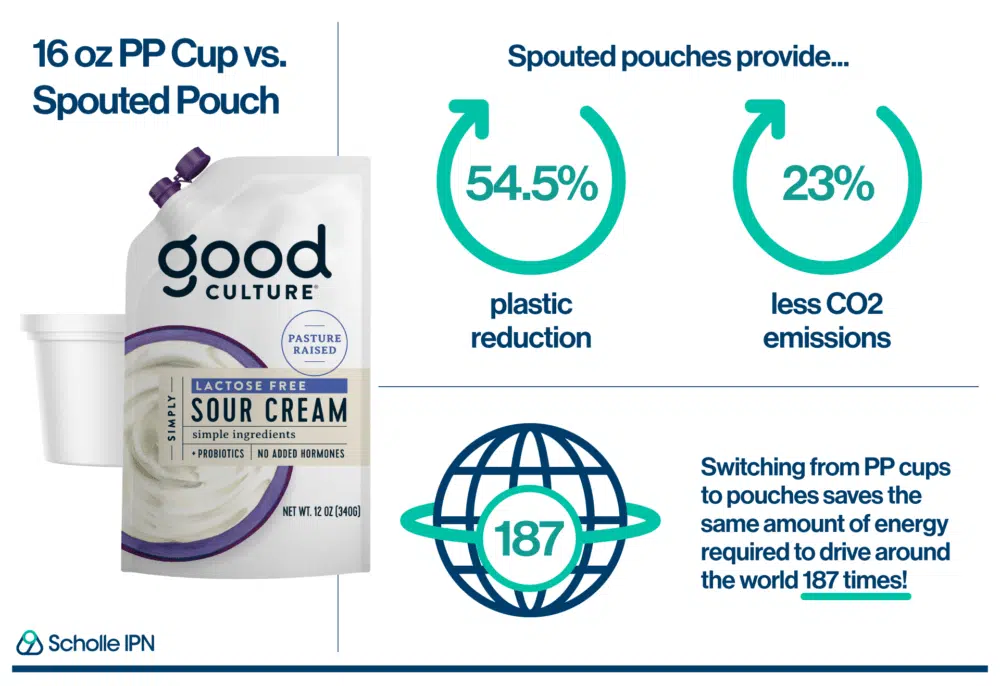

The results speak for themselves: a traditional 16-ounce PP cup requires more materials and energy to process and transport than pouches. In the manufacturing process, spouted pouches provide a 54.5% reduction in plastic use, and release 23% less CO2 emissions. We estimate that within a year, a switch from PP cups to pouches saves as much energy as needed to drive 1,484,216 miles (enough to drive around the world 187 times) or the equivalent of diverting 128 passenger vehicles off the road.

The results speak for themselves: a traditional 16-ounce PP cup requires more materials and energy to process and transport than pouches. In the manufacturing process, spouted pouches provide a 54.5% reduction in plastic use, and release 23% less CO2 emissions. We estimate that within a year, a switch from PP cups to pouches saves as much energy as needed to drive 1,484,216 miles (enough to drive around the world 187 times) or the equivalent of diverting 128 passenger vehicles off the road.

We can provide your business a total flexible packaging solution. Get in touch with us and we’ll explore ways you can implement a more sustainable packaging system.