Five Ways We Practice Sustainability at Scholle IPN

April 21, 2022

Earth Day is a great time to celebrate sustainability, but at Scholle IPN, we implement sustainable practices year-round. Being committed to the well-being of our planet isn’t an end goal but a journey that requires thoughtfulness, intentional action, and accountability.

For us, sustainability starts with one key idea: we can do more with less. We are dedicated to reducing our environmental footprint, from flexible packaging formats like bag-in-box and pouches that use fewer materials to total solutions that provide companies with vertically-integrated packaging systems. Furthermore, we want to make it easier for others to choose responsible packaging solutions and work to push innovative new formats like tethered fitments and recycle-ready films.

But it doesn’t end with our product line. Scholle IPN has locations across the globe, and many of our plants and offices have translated our company-wide commitment to sustainability in ways that make sense for their surrounding community. These initiatives go beyond daily operations, inviting our team members to brainstorm creative ways to set an example as a leader in source reduction and responsible energy consumption.

Here are five ways we practice sustainability worldwide:

1. Brazil’s Green Belt Project

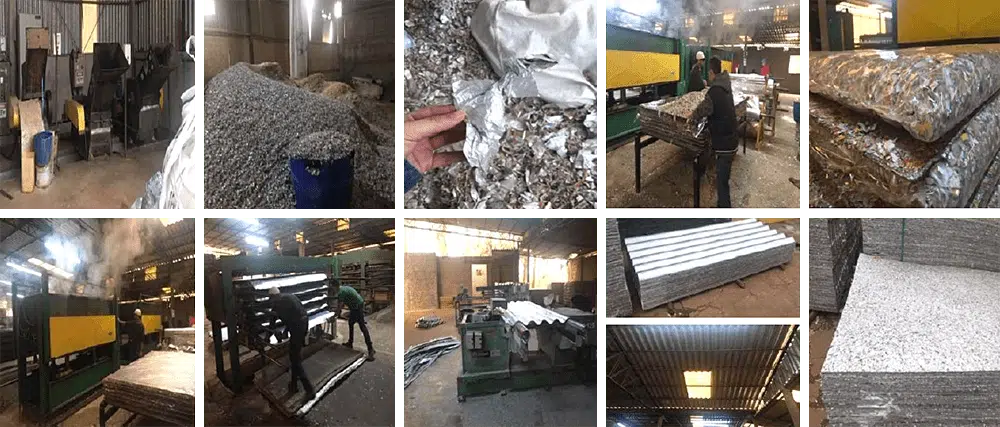

One of the principles we apply to our supply chain is the circular economy model: instead of consuming resources in a linear model—where often the endpoint is a landfill—we find ways to reuse and repurpose materials that would otherwise be wasted or thrown away.

Our plant in Brazil decided to find a way to repurpose old scrap metal by partnering with Brasiplac. This organization takes old pieces and presses them into usable roofing tiles. This might seem small, but our plant diverted over 100,000 kilograms of scrap metal into roofing tiles in just three months—all without using harsh chemicals or other processes that would harm the planet.

The Green Belt Project was an initiative our team in Brazil decided to embark on: they identified scrap metal as a source of waste and worked to find a partner who could repurpose the materials.

2. Brazil’s Closed Water System

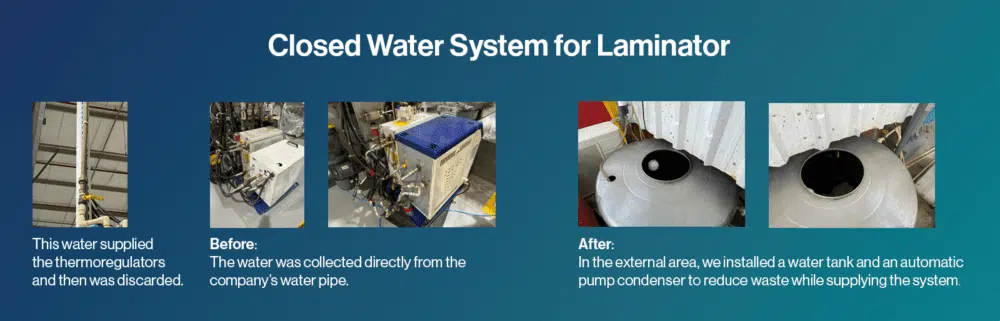

Our Brazil team has taken on multiple projects to improve sustainability at their plant. Initially, the plant used water from their water line to cool down four thermoregulators and would then discard the water once it was too hot and unusable.

The team identified this system as a waste point and decided to develop a new, closed-loop system that would still safely cool down their thermoregulators while not wasting water.

They developed a regenerative water system that would cycle the same water through the thermoregulator system. The pump would help cool water down after it became too hot, cycling the same water through the system. The closed-loop pump made water reusable for the thermoregulators while keeping the machines safely cooled.

3. Solar Panels in Suzhou, China

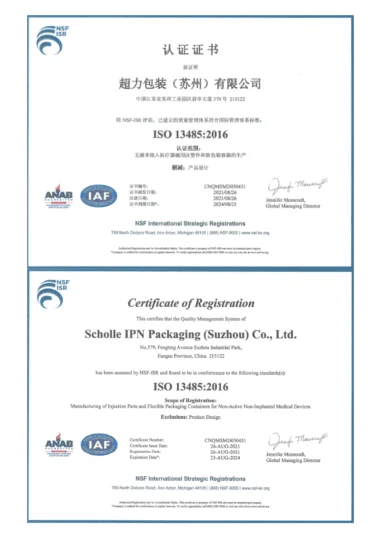

Our plant in Suzhou, China, has always set an example for going above and beyond in terms of sustainability.

They recently received ISO 13485 certification, recognizing the plant for going above and beyond in their quality management systems for manufacturing injection molding parts and flexible packaging for non-active and non-implanted medical devices. The team also presented Scholle IPN’s Environmental, Social, and Governance (ESG) report at the Chemicals Packaging and Logistics Forum. They were asked to outline the current state of affairs regarding packaging formats.

The plant decided to reduce its power usage by investing in natural resources and improving its existing infrastructure. Along with installing a charcoal-activated air filtration system, they placed 2,728 solar panels on the roof of their facility, which generates 1.03 million kilowatts of energy annually.

By switching to solar panels, the plant has saved 371 tons of coal per year, reduced carbon emissions by 973 tons per year, reduced sulfur dioxide emissions by 27.84 tons per year, reduced nitrogen oxide emissions by 13.92 tons per year, and reduced soot emissions by 252 tons per year. This switch was so successful that the Suzhou plant teamed up with our Adelaide location in Australia to install more solar panels.

4. Gold Medal Certification in The Netherlands

We’re proud of our achievements and thrilled to share the examples above, but we also believe in constantly assessing our impact and inviting others to give their opinions and feedback. That’s why we work with EcoVadis, a sustainability assessment tool that rates a company’s corporate social responsibility (CSR) and how well they’ve incorporated the values of their CSR into their workflow.

Third-party assessment tools are incredibly valuable to us. As you read above, our Suzhou plant received its ISO 13485 certification. Our Brazil and Chile plants continue to work with and renew their FSSC 22000 certification, ensuring that both plants offer the highest-quality food-safe packaging. And in January of 2022, our Jellinghaus plant in The Netherlands received a gold medal rating from EcoVadis.

Third-party assessment tools are incredibly valuable to us. As you read above, our Suzhou plant received its ISO 13485 certification. Our Brazil and Chile plants continue to work with and renew their FSSC 22000 certification, ensuring that both plants offer the highest-quality food-safe packaging. And in January of 2022, our Jellinghaus plant in The Netherlands received a gold medal rating from EcoVadis.

The EcoVadis assessment tool evaluates sustainability using four dynamic metrics: environment, labor and human rights, ethics, and sustainable procurement. Our gold medal certification means that we’re in the top 5% of all companies analyzed by EcoVadis—they have worked with over 85,000 companies in 160 countries.

5. Community Volunteer Efforts in North America and India

For Earth Day 2021, Scholle IPN CEO Ross Bushnell penned a letter urging others to make a long-term commitment to sustainability. “While no single action will solve all these issues,” he wrote, “each one of us can make a positive impact if we simply commit to do our part.”

Sustainability efforts don’t need to be big gestures. Many of our plants take on small, community-focused projects, working together to identify ways they can better serve the environment locally.

Sustainability efforts don’t need to be big gestures. Many of our plants take on small, community-focused projects, working together to identify ways they can better serve the environment locally.

Employees regularly participate in local neighborhood cleanups at our facility in Peachtree City, Georgia. In Palghar, India, employees set up a tree-planting drive around an industrial site to reduce air pollution and maintain and care for the trees.

Our goal with these initiatives is to inspire others to start incorporating sustainable practices into their own lives, no matter how small a singular action may seem—and we’re especially interested in inspiring the next generation of leaders to learn how they can make an impact.

At our Northlake, Illinois location, we regularly invite students and young thinkers to engage with our engineers and learn about their work. We hope to encourage young people to explore engineering and STEM careers in the future. Still, we also hope that they leave understanding the importance of environmental sustainability and how they can reduce their ecological footprint.

Our Sustainable Future

We’re proud of all these different initiatives because it shows that environmental responsibility isn’t a one-way street. There are multiple pathways to building a sustainable future. If you read this article and only leave with one thing, we hope it’s that you can practice reducing your environmental footprint right now and take a small step towards a healthier planet today.