Pharmaceutical Packaging

Bag-in-box and pouch packaging provide eco-conscious solutions that protect your pharmaceutical products from contamination and environmental conditions while making them safer and easier to dispense with precision.

Bag-in-Box for Pharmaceuticals

Trust our rigorously-tested flexible packaging products to keep your pharmaceuticals secure. Our innovative bag-in-box systems include a wide range of film, fitments, and filling equipment for a total packaging solution engineered to protect your products from fill through end use. We provide:

- Aseptic packaging technology for a shelf-stable, preservative-free product—no refrigeration required.

- Superior product evacuation and extended shelf life.

- UN-Certified packaging that minimizes costs throughout your supply chain.

- Solutions that reduce your environmental impact and leave less packaging waste behind.

Institutional Bag-in-Box for Pharmaceuticals

Safely dispense pharmaceutical products with our secure bag and fitment systems, ideally designed for dosing, dispensing, collection, and metering in healthcare settings. We provide:

- Controlled, precise dispensing systems designed for accurate mixing.

- Sterile, closed-loop systems that minimize contact exposure.

- Durable films for aggressive or sensitive products with a wide variety of pH ranges.

Industrial Bag-in-Box for Pharmaceuticals

Use our industrial-sized flexible IBCs, tote liners, and drum liners to safely transport your pharmaceutical products and ingredients in packaging that offers cost savings throughout the supply chain. These packages facilitate:

- Clean and safe delivery of base materials to your production facility.

- Streamlining, demanding less resources to clean and service bulk containers.

- Unique films designed especially for aggressive chemical products.

Pouch Packaging for Pharmaceuticals

Expand your market potential with our secure, spouted pouches—an ideal solution for smaller sizes of pharmaceutical products used in dosing, collection, and metering, where mix ratios are critical. And for patients with dysphagia, our aseptic pouches are ideal for providing premixed, thickened food and beverage products in a shelf-stable package with extended secondary shelf life—and no preservatives or refrigeration required.

- Package precise amounts for controlled delivery of sensitive ingredients.

- Maximum product evacuation with minimal mess.

- Typically lower carbon footprint than heavy, rigid alternatives.

- Better product-to-package ratio than rigid formats like jars and vials.

Pre-Made Pouches for Pharmaceuticals

Our CleanPouch® system helps you streamline your operation by focusing on your product while relying on us to deliver quality pouch packaging. These pre-made spouted pouches are delivered on rail systems, so it’s easy to get your filling operation up and running.

Benefits of the CleanPouch® System:

- Various film options, including transparent for product and volume visibility.

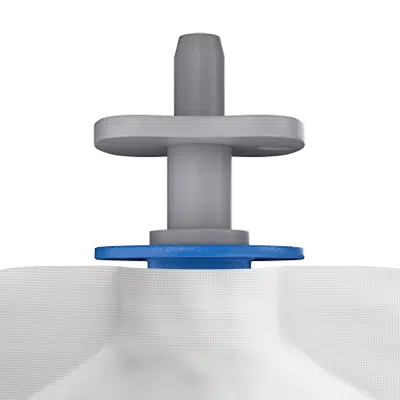

- Secure seals with customizable spout and cap options.

- Dynamic filling equipment for small and full-scale, automated operations.

Pouch Solutions for Pharmaceuticals

If you’re interested in getting started or are already producing pouches using horizontal form-fill-seal (HFFS), count on us for the high-quality materials needed for making your pouches:

- Films: Choose from our wide range of options from traditional foil to consumer-preferred transparent. Plus, our RecShield™ pouch film can be recycled with other polyethylene films.

- Fitments: Select from our wide variety of unique and innovative pouch spouts and caps engineered for the rigors of HFFS production.

- Equipment: Use our combined pouch fitments and barrier films in tandem with the top-of-the-line Bossar BMS 4.2 for a complete HFFS pouch packaging solution.