On-Demand Webinar: Flexible Packaging for Ecommerce

January 15, 2021

Flexible Packaging for the Future

Discover How Flexible Packaging Innovations Contribute to Environmental Sustainability and Address Changing Consumer Habits

Discover How Flexible Packaging Innovations Contribute to Environmental Sustainability and Address Changing Consumer Habits

Last December, Scholle IPN hosted a webinar to address new shopping behaviors and talk about how flexible packaging can offer sustainable and reliable ecommerce solutions to a growing market. If you missed it, check out the summary below or watch the on-demand webinar now!

Watch the WebinarFast-Track Session Summary

This fast-track session, called “Flexible Packaging for Ecommerce,” invited experts to discuss the importance of flexible packaging to build consumer loyalty, reduce waste, and to capture a growing segment of the market that is only anticipated to grow more. Webinar attendees spanned across the globe as more and more companies look to flexible packaging as a solution to common ecommerce distribution and delivery systems.

Mintel and Why Ecommerce is Important

“We’ve heard so much…about the ‘new normal,’ and the way Mintel looks at it, there is nothing new about what is going on,” said David Luttenberger, Global Packaging Director for Mintel, a leading data and market research provider. Luttenberger kicked off the presentation by reminding attendees that finding flexible packaging solutions isn’t about solving new problems now, but about creating new and innovative solutions for the future. “We’re always hoping you look forward—about what’s next.”

“We’ve heard so much…about the ‘new normal,’ and the way Mintel looks at it, there is nothing new about what is going on,” said David Luttenberger, Global Packaging Director for Mintel, a leading data and market research provider. Luttenberger kicked off the presentation by reminding attendees that finding flexible packaging solutions isn’t about solving new problems now, but about creating new and innovative solutions for the future. “We’re always hoping you look forward—about what’s next.”

The focus of Luttenberger’s research was changing consumer habits during COVID-19. In his presentation, he identified ecommerce trends, and differentiated between trends he believed would stick versus ones that would fade. In particular, he noted that 42% of consumers are buying household products online, and that 42% of consumers anticipate continuing to purchase household items online.

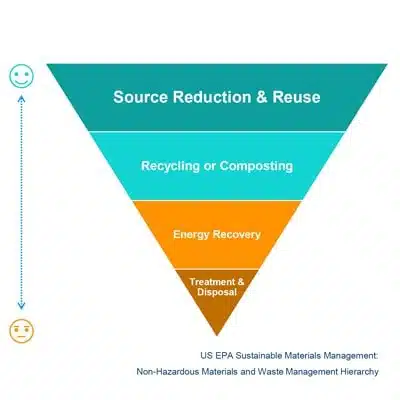

At the end, Luttenberger called for solutions-based innovations to flexible packaging, calling attention to three key factors: “Durability, environmental responsibility, and solutions for ecommerce packaging and flexibles that the consumers can look at and understand why it’s different and what that difference means to their lives.”

Scholle IPN and How Flexible Packaging Impacts Ecommerce

Brent Haynam, Commercial Engineering Manager for Scholle IPN spoke next, and highlighted the need for long-term solutions that address both growing population needs and environmental concerns, along with the rise of ecommerce—essentially, ecommerce is here to stay but we can’t ignore how wasteful current packaging solutions can be. “We’re using existing, oftentimes rigid packages that work great for certain applications but not necessarily for this channel. And then we’re having to add a lot of secondary and tertiary packaging to these products, which increases costs but doesn’t guarantee that the products are going to survive delivery.”

Brent Haynam, Commercial Engineering Manager for Scholle IPN spoke next, and highlighted the need for long-term solutions that address both growing population needs and environmental concerns, along with the rise of ecommerce—essentially, ecommerce is here to stay but we can’t ignore how wasteful current packaging solutions can be. “We’re using existing, oftentimes rigid packages that work great for certain applications but not necessarily for this channel. And then we’re having to add a lot of secondary and tertiary packaging to these products, which increases costs but doesn’t guarantee that the products are going to survive delivery.”

Haynam tied the environmental sustainability of flexible packaging to adaptability. “We have packages that were intended for retail, on the shelf market getting moved into the ecommerce realm without necessarily the packaging changing.” Flexible packaging, he says, not only can adapt to a variety of shipping scenarios, but can be ideal for distribution companies looking for SIOC (ships in its own container) solutions to simplify the supply chain. “A picker grabs a case, they throw it on the line, slap a label on it, and it gets shipped—you have limited handling and this is the most desirable position for distribution facilities and ecommerce companies.” In this scenario, not only is efficiency improved but the amount of product used to ship items is drastically reduced.

Georgia-Pacific and What Bag-In-Box Formats Work Best in Ecommerce

Lastly, Keri Wilson, Senior Packaging Innovation Engineer for the Georgia-Pacific (GP) Innovation Institute, took over, and spoke about the work GP is doing to rigorously test and develop new packaging materials.

Lastly, Keri Wilson, Senior Packaging Innovation Engineer for the Georgia-Pacific (GP) Innovation Institute, took over, and spoke about the work GP is doing to rigorously test and develop new packaging materials.

She detailed the work that each GP lab does to test the durability of their packaging products. “We have conditioning chambers where we are able to condition packages with everything from refrigerated all the way to freezing conditions so we can simulate what the package is going through.”

Specifically, Wilson focused on the work the institute does in their transportation lab, where researchers mimic and study what a package goes through as it moves from pallet to loading to delivery by a distribution center. “Two years ago, we partnered with Scholle IPN to develop a bag-in-box solution to solve the market need for shipping liquids in the ecommerce environment that can pass SIOC Amazon protocols.”

Learn More

Learn more about our flexible packaging options, including institutional Bag-in-Box solutions, and how flexible packaging supports source reduction and environmental sustainability.