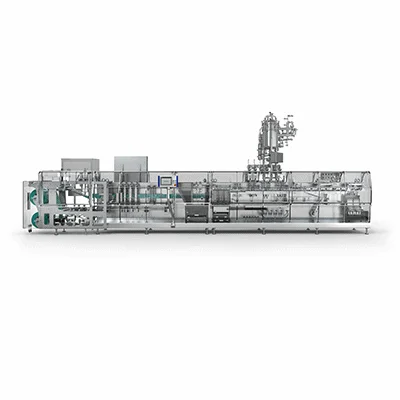

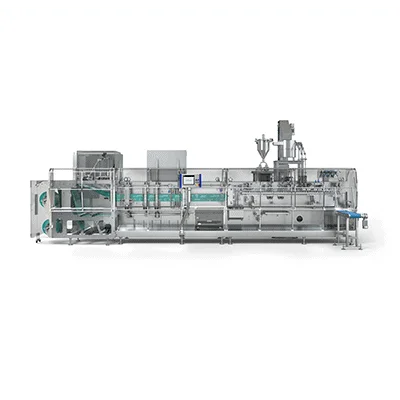

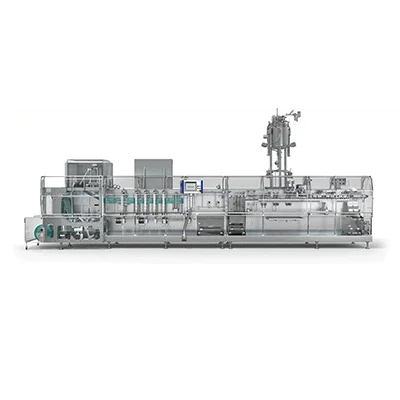

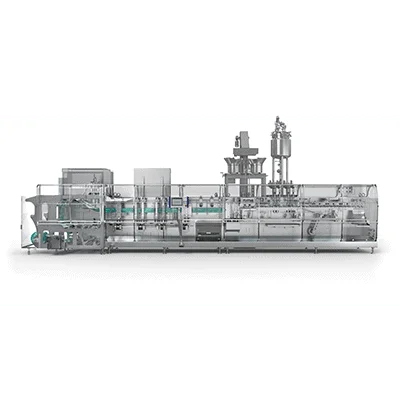

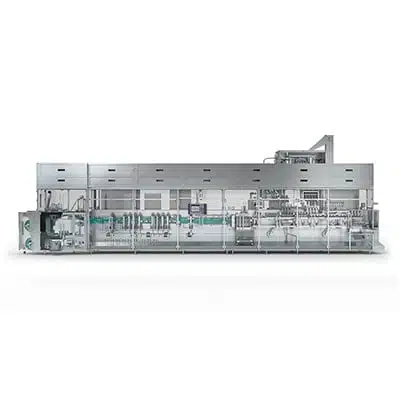

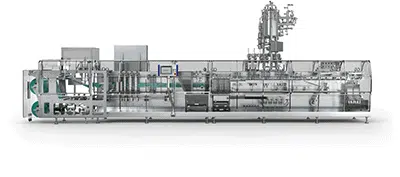

SIG Motion 180 Servo 3.3

This horizontal form-fill-seal machine works in simplex, duplex and triplex, forming and filling pouches within a range of 80mm x 80mm to 165mm x 300mm. It can reach an output of up to 160 pouches per minute and can fill up to 1500 cc of product.

- Features HMI display for instructions and troubleshooting

- Boasts cutting die for pouches with special shapes

- Parallel motion of sealing bars enables improved seal quality

Product Specifications

Key Features

Full Servo Motion

This smart servo-control system allows independent operation between the different stations, offers great reliability and little maintenance.

Walking Beam

Traditional walking beam transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

Retort

Sterilization of premade pouches and film from reel by means of an autoclave. Retort machines are suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté.

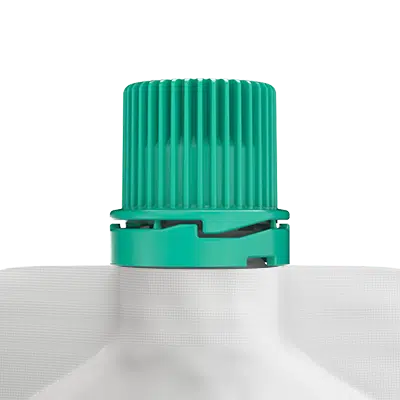

Clean & Ultra-Clean

Clean and ultra-clean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

Mirror Machine

Placing one standard machine in front of the other operating the opposite direction makes operating easier and reduces staff required to control them.

For more information, please visit bossar.com.

Known Process Applications

Hot-Fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Ambient

Occurs when a product is filled into a package with no additional sterilization treatment.

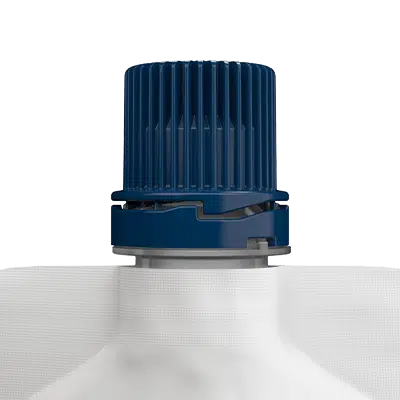

Ultra-Clean (ESL)

Uses UV, laminar flow, and/or hydrogen peroxide to achieve high sterility levels for short shelf-life products.

Filling Method

Common Package Sizes

400mL to 1500mL (13.5 fl oz to 50.7 fl oz)

Typical Markets

Pouch Size and Speed

| Pouch Style | Format Range (mm) WxH | Maximum Volume | Filling Speed | |||

|---|---|---|---|---|---|---|

| Minimum | Gusset | Maximum | Gusset | (c.c.) | (Pouches per minute) | |

| FLT-2 | 80 x 80 | n/a | 165 x 300 | n/a | 800 | 130 |

| FLT-3 | 80 x 80 | n/a | 110 x 300 | n/a | 400 | 180 |

| STU-2 | 80 x 80 | 25 | 165 x 300 | 48 | 1500 | 130 |

| STU-3 | 80 x 80 | 25 | 110 x 300 | 32 | 525 | 180 |

Equipment Specifications

| Transport System | Servo-motorized grippers |

| Reel Diameter | 600mm (23.6in) |

| Reel Width | 360mm (14.2in) |

| Reel Core | 70mm to 76 mm (2.8in to 3in) |

| Filling stations | Up to 3 |

| Machine dimensions (L x W x H) | 9940mm x 1560mm x 2100mm (391.3in x 1.4in x 2.7in) |

| Electrical Consumption | 20kW |

| Air Consumption | 700L/min (184.92gal/min) |

| Electrical Data | 200-480V / 50-60 Hz / N + G / 3Ph (others under request) |

| PLC | ALLEN BRADLEY / SIEMENS (others under request) |

| Noise Level | <70 dB |

| Safety | CE & UL Standards |

Footprint

9940mm x 1560mm x 2100mm (391.3in x 1.4in x 2.7in)