Scholle IPN Continues To Lead The Way in Food Safety

February 26, 2021

Our Brazil and Chile plants renewed their FSSC 22000 certification, ensuring the highest quality in food safety

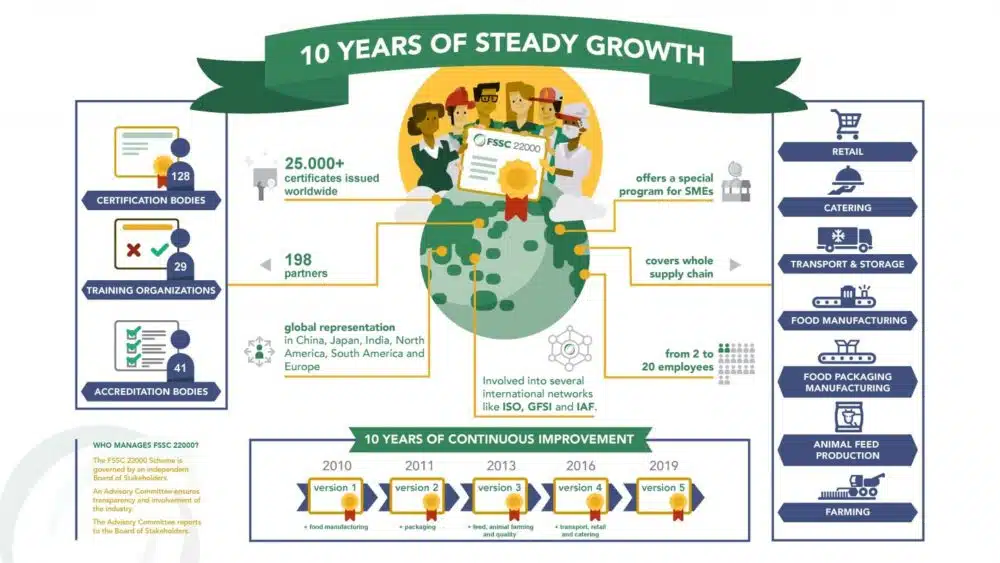

Scholle IPN is proud to announce that our Brazilian and Chilean units maintained their Food Safety System Certification (FSSC) 22000. FSSC 22000 is a global organization, recognized by the Global Food Safety Initiative (GFSI), that works with safety professionals to develop international standards and protocols that ensure food is packaged and delivered safely to consumers.

Scholle IPN is proud to announce that our Brazilian and Chilean units maintained their Food Safety System Certification (FSSC) 22000. FSSC 22000 is a global organization, recognized by the Global Food Safety Initiative (GFSI), that works with safety professionals to develop international standards and protocols that ensure food is packaged and delivered safely to consumers.

“FSSC 22000 [established] the first international standard for implementing a Food Safety Management System,” says Fabio Carias, Assured Quality Coordinator for Scholle IPN. Before the FSSC 22000 and the GFSI, there were no agreed-upon protocols for how food should be stored to protect against contamination. Subsequently, a number of food crises arose that threatened the safety and confidence of the global food supply chain.

At Scholle IPN, we strive to put safety first—but we also pride ourselves in being transparent with our consumers. Our continued commitment to maintaining our FSSC 22000 designation is a promise to our customers that we will always put their wellbeing above all else.

A Continued Commitment to Safety

This is the eighth year in a row that our Brazilian branch has received FSSC designation and the third year for our newer Chilean plant. “Since February 2013, Scholle IPN has been certified in FSSC 22000 standards, guaranteeing the safety of its production processes, as well as of the products supplied to the food market,” Carias says.

The FSSC 22000 audit considers a number of factors, including interactive communication, risk management, and control systems. Companies volunteer to adhere to FSSC 22000 standards, perform a self-audit of their internal systems based on established protocols, and then are assessed by an approved FSSC 22000 auditor who verifies that the company follows guidelines. An FSSC 22000 designation is good for three years with auditors checking in yearly.

In particular, the FSSC 22000 narrows in on Hazard Analysis and Critical Control Points (HACCP). “HACCP is a methodology based on preventive principles and concepts aiming, through a systemic approach, to identify and evaluate points or steps where it can be controlled hazards and, consequently, ensure food safety,” Carias explains. Essentially, the FSSC 22000 protocols help companies identify potential hazards and put preventative measures in place that are easy to assess and systematic in their implementation.

Taking the Extra Step

Although the FSSC 22000 sends its own auditors, Scholle IPN has taken the extra step to designate an internal team that continuously ensures safe practices within our facilities. “To ensure that no contamination occurs, Scholle IPN has a multidisciplinary food safety team in its structure,” Carias says, “which, through hazard analysis and critical control points (HACCP), monitors and evaluates any and all changes that occur in the manufacturing process of the products.”

“In addition to this,” Carias goes on to explain, “Scholle IPN follows the guidelines of Good Manufacturing Practices (GMP) and the facilities [we operate in] were built in order to facilitate the maintenance and cleaning operations.” GMP standards are set to ensure that a product is made consistently and according to quality standards.

All this is to say that we care about safety and are committed to rigorous testing to ensure we’re doing everything we can to protect customers—a simple check on a list isn’t good enough for us. We take a holistic approach to food safety by implementing and innovating our own internal systems and inviting outside certifiers to encourage transparency and accountability.