Scholle IPN’s Eisfeld, Germany, Site Offers New Barrier Film Capabilities

May 13, 2020

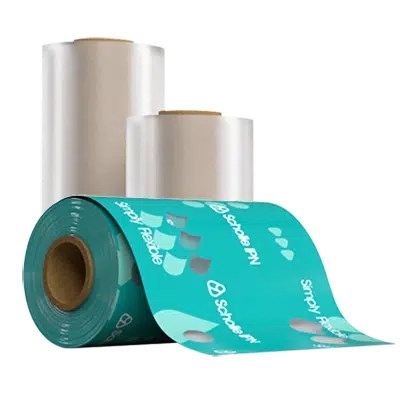

On May 13, 2020, our Eisfeld, Germany, location reached a major milestone: installing its first high-barrier film extruder. Being the largest single investment at this location in over a decade, this film extruder is the type of innovation that will set the tone for a new era of film production. With its newfound capabilities and focus on quality, Scholle IPN’s EMEA packaging production has never looked better.

Barrier Film Capabilities in EMEA

When asked what new capabilities the new film extruder provides to Scholle IPN EMEA, Lutz Frischmann, General Manager Eisfeld, stated: “We can now produce a 9-layer structure for the first time, which allows us to continue developing recyclable structures with barrier properties.” Luis Alberto Santini Torres, Director, Film Technology, agreed and added: “The 9-layer configuration allows us to be highly flexible like never before.”

When asked what new capabilities the new film extruder provides to Scholle IPN EMEA, Lutz Frischmann, General Manager Eisfeld, stated: “We can now produce a 9-layer structure for the first time, which allows us to continue developing recyclable structures with barrier properties.” Luis Alberto Santini Torres, Director, Film Technology, agreed and added: “The 9-layer configuration allows us to be highly flexible like never before.”

With the new extruder in place, we are confident that our European business unit will be able to market themselves as a provider of more diverse packaging for products such as dairy, juice, wine, and coffee. The new extruder also makes it feasible for multilayer bag-in-box and pouch film structures to eliminate the lamination process, acting on its own as a film barrier without it. When it comes to supplying our products from here on out, Torres feels that it could go one of two ways: selling materials to other converters or directly to final customers.

Scholle IPN has always focused on providing products of high quality. Our profound knowledge and experience in diverse packaging products gives us the one-up on our competition. When asked what sets Scholle IPN apart from other suppliers, Frischmann was confident in his answer. “Barrier film and recyclable structures, combined with our development and experience in film extrusion and production of taps and spouts gives Scholle IPN EMEA, along with our customers, a huge advantage for the future.”

Scholle IPN has always focused on providing products of high quality. Our profound knowledge and experience in diverse packaging products gives us the one-up on our competition. When asked what sets Scholle IPN apart from other suppliers, Frischmann was confident in his answer. “Barrier film and recyclable structures, combined with our development and experience in film extrusion and production of taps and spouts gives Scholle IPN EMEA, along with our customers, a huge advantage for the future.”

The investment of the new extruder now puts Scholle IPN EMEA on track to be positioned as a total film solutions supplier.

Introducing a 9-layer structure has been no easy feat, but they have delivered a groundbreaking product and continue to live up to Scholle IPN’s standard of innovation. Learn more about our films.