History of SIG’s bag-in-box and pouch packaging

January 1, 2020

Our story

At SIG, innovation is not just a word; it’s a mission to strive for each and every day. With a seemingly endless number of industry firsts spanning the life of our company, there is no doubt that SIG has grown into one the world’s leading manufacturers of packaging products, automated filling equipment, and closures.

Scholle Packaging

Scholle Packaging was founded in 1947. As a newly founded company, Scholle invented and marketed the first bag-in-box packaging, the first of many milestones we would come to achieve as a company. Bag-in-box packaging was initially created for the use of safe transportation and dispensing of battery acid to automotive filling stations and repair shops, and it quickly found its way into other industries as well.

Scholle Packaging was founded in 1947. As a newly founded company, Scholle invented and marketed the first bag-in-box packaging, the first of many milestones we would come to achieve as a company. Bag-in-box packaging was initially created for the use of safe transportation and dispensing of battery acid to automotive filling stations and repair shops, and it quickly found its way into other industries as well.

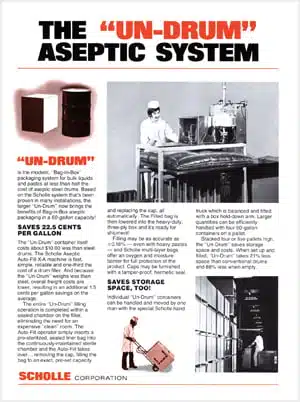

In the 1970s, the aseptic filling process was perfected, which allowed Scholle to further advance its initial product line into food and beverage industries, and soon entire flexible packaging systems were possible.

Milestones for SIG bag-in-box and pouch

There’s a reason the SIG name is synonymous with bag-in-box and pouch packaging systems. We began our journey with the development of the very first bag-in-box packaging system, which assured storage of consumer items to be of high quality and safety during transportation. This is where the innovation started, but it is most definitely not where it stopped. Over the years, SIG pioneered countless ways to increase consumer convenience and safety, while expanding the quality of its packaging systems. We have many company- and industry-wide milestones under our belt. Our major achievements can be broken down and categorized into success with total packaging systems, development of filling equipment and technology, introduction into various markets, and aseptic work.

There’s a reason the SIG name is synonymous with bag-in-box and pouch packaging systems. We began our journey with the development of the very first bag-in-box packaging system, which assured storage of consumer items to be of high quality and safety during transportation. This is where the innovation started, but it is most definitely not where it stopped. Over the years, SIG pioneered countless ways to increase consumer convenience and safety, while expanding the quality of its packaging systems. We have many company- and industry-wide milestones under our belt. Our major achievements can be broken down and categorized into success with total packaging systems, development of filling equipment and technology, introduction into various markets, and aseptic work.

Flexible Packaging Systems

Expanding on the initial bag-in-box packaging, we have continued to evolve and create a more efficient means to package products. There have been many milestones within the company that come from just flexible packaging systems alone. For example, we were the first to:

Expanding on the initial bag-in-box packaging, we have continued to evolve and create a more efficient means to package products. There have been many milestones within the company that come from just flexible packaging systems alone. For example, we were the first to:

- Develop bag-in-box packaging.

- Injection-mold fitments for more efficient filling.

- Commercialize 300-gallon aseptic bulk bags.

- Develop metalized polyester gas-barrier film for liquid packaging.

- Offer 350-gallon bag-in-bin systems.

- Introduce dispensing fitments attached to pouches.

Pouch Innovations

Reliable pouch packaging systems have been at the core of our mission for decades. We have long been developing innovative and high-quality products manufacturing in clean room environments with the goal of enabling growth of pouch systems. For example, we:

Reliable pouch packaging systems have been at the core of our mission for decades. We have long been developing innovative and high-quality products manufacturing in clean room environments with the goal of enabling growth of pouch systems. For example, we:

- Specialize in plastic components and pouch packaging for food, non-food, and healthcare markets.

- Developed and patented Clean-Clic® technology for closed-loop pouch dispensing.

- Were the first to develop a pre-made aseptic spouted pouch.

Filling Equipment and Technology

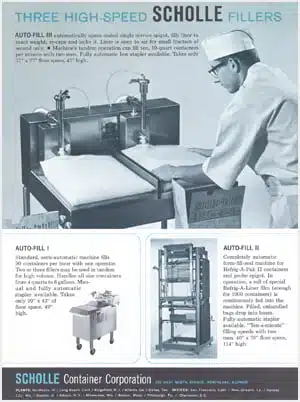

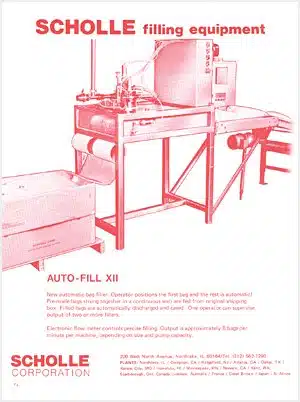

The developments we have seen in filling equipment and technology truly demonstrate the lengths to which our innovative spirit can take us. After recognizing the success of bag-in-box, we implemented some improvements in technology to allow for improved overall equipment efficiency (OEE) and packaging system quality. For example, we were the first to:

The developments we have seen in filling equipment and technology truly demonstrate the lengths to which our innovative spirit can take us. After recognizing the success of bag-in-box, we implemented some improvements in technology to allow for improved overall equipment efficiency (OEE) and packaging system quality. For example, we were the first to:

- Provide automatic bag-in-box filling equipment.

- Use Cobalt radiation to sterilize bags.

- Integrate automatic cartoning equipment with web fillers.

- Offer form-seal-fill technology for bag-in-box packaging.

- Introduce induction sealing to replace traditional heat seal.

Markets

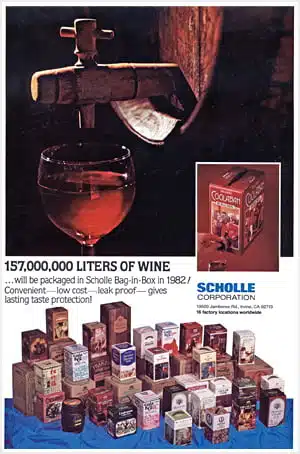

Throughout our history, we have been able to break through and remain competitive in various markets. After developing bag-in-box packaging for the safe transportation of battery acid, we entered other markets with similar success. These markets include dairy, wine, soft drinks, and more. For example, we were the first to:

Throughout our history, we have been able to break through and remain competitive in various markets. After developing bag-in-box packaging for the safe transportation of battery acid, we entered other markets with similar success. These markets include dairy, wine, soft drinks, and more. For example, we were the first to:

- Supply bag-in-box filling equipment for the dairy industry.

- Develop bag-in-box packaging for the wine industry.

- Supply the tomato industry with its first aseptic bags and filling equipment.

- Offer fillers for long-life UHT dairy products.

- Supply bag-in-box packaging for post-mix syrup.

- Supply bag-in-box packaging for liquid egg.

Film Technology

As a pioneer of barrier film technology used in flexible packaging for the last 30 years, we have established a reputation for providing customers with protection and performance they can rely on. Being both economical and sustainable, our film preserves freshness and prolongs shelf life for a diverse range of products, from fresh food and beverages to pH-sensitive products. Just as impressive as our history and experience is our future with Film Technology. The introduction of the RecShield™ has brought us even closer to our mission for the future: a circular economy. RecShield is a recyclable, transparent film for hot-filled or aseptically-sterilized products in spouted pouches. Because of our ability to think outside the box, pouch products do not have to compromise on barrier protection to provide an environmentally-conscious alternative for packaging.

As a pioneer of barrier film technology used in flexible packaging for the last 30 years, we have established a reputation for providing customers with protection and performance they can rely on. Being both economical and sustainable, our film preserves freshness and prolongs shelf life for a diverse range of products, from fresh food and beverages to pH-sensitive products. Just as impressive as our history and experience is our future with Film Technology. The introduction of the RecShield™ has brought us even closer to our mission for the future: a circular economy. RecShield is a recyclable, transparent film for hot-filled or aseptically-sterilized products in spouted pouches. Because of our ability to think outside the box, pouch products do not have to compromise on barrier protection to provide an environmentally-conscious alternative for packaging.

Aseptic Packaging Technology

When it comes to aseptic packaging, a key element is that it is free of contamination and secures the product while in transport. At SIG, we have upheld our reputation for bringing exceptional value to our customers. We pride ourselves on our ability to deliver products the way they are supposed to be experienced. Some of the groundbreaking ways in which we manage to do this are by constantly working towards more efficient solutions when it comes to aseptic equipment. For example, we were the first to:

When it comes to aseptic packaging, a key element is that it is free of contamination and secures the product while in transport. At SIG, we have upheld our reputation for bringing exceptional value to our customers. We pride ourselves on our ability to deliver products the way they are supposed to be experienced. Some of the groundbreaking ways in which we manage to do this are by constantly working towards more efficient solutions when it comes to aseptic equipment. For example, we were the first to:

- Provide aseptic filling equipment.

- Aseptically empty product from bag-in-box containers.

- Commercialize the first aseptic-capable, pre-made spouted pouch and filling equipment.

Our diverse product range allows for continued growth within our current markets and the opportunity to further expand into new markets. Our innovative propensities will continue to allow the breakthroughs of the past to carry us to new achievements in the future.