Bossar Meets the Monomaterials Challenge

In a recent Packaging Europe article, the question “How can lightweight, flexible packaging with low CO2 emissions be made from recyclable materials?” is asked and answered in light of how digitalization can be leveraged to deliver innovation that facilitates the development of sustainable packaging. The article walks through a collaborative project with Bossar Packaging S.A., a leading horizontal form-fill-seal packaging machine designer and manufacturer.

In a recent Packaging Europe article, the question “How can lightweight, flexible packaging with low CO2 emissions be made from recyclable materials?” is asked and answered in light of how digitalization can be leveraged to deliver innovation that facilitates the development of sustainable packaging. The article walks through a collaborative project with Bossar Packaging S.A., a leading horizontal form-fill-seal packaging machine designer and manufacturer.

Packaging machine specialist Bossar Packaging S.A. has been investing heavily in developing, together with Scholle IPN, recyclable solutions for pouches combining mono-material film structures with recyclable components. The article writes, “One key factor in making recycling-friendly pouches is stringent control of sealing temperature, time, and pressure to achieve an excellent seal quality, and this required Bossar’s materials and machine specialists to employ their collective expertise. The result is a novel machine design that consists of a pouch maker and pouch filler.”

How Does It Work?

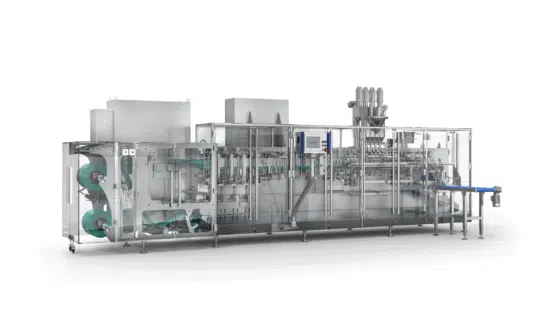

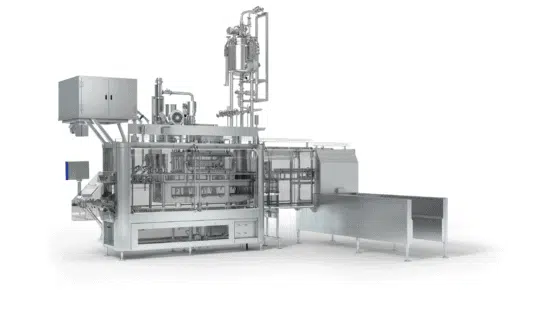

The i-Bossar Pouch Maker (i-BPM) machine seals and cools the pouch in a single step, which reduces the stress on the film. This is especially important for monomaterials such as polyethylene films that are sensitive to stretching: as the pouch maker operates continuously, the films are not stretched during pouch production.

The pouches are then transferred to the new Bossar Clean Filler (BCF) linear pouch filler. By separating the pouch making from the filling and sealing, Bossar can ensure an excellent sealing quality while providing a high level of flexibility to produce multiple pouch formats with minimal changeover time.

Learn More

Interested in learning more? Read the full article or visit Bossar.com to browse their full-range of equipment.