The total packaging solutions leader

Striving for better is at the core of everything we do. It inspires us to create the most sustainable packaging solutions across categories and channels. It inspires us to deliver innovative and flexible solutions, to pioneer technology, and to ultimately help transform customers' business for the better.

The strategy that drives us forward

SIG stands for better – delivering better for customers, for consumers, and for the world.

Our goal is to deliver the most sustainable, innovative, fast and flexible packaging solutions in carton, pouch & bag-in-box across categories and channels. This work starts within.

Our compass guides us every moment of every day. We work together to find better solutions for our customers, their consumers, and our own business. When we do this to the best of our ability, we find sustainable solutions which benefit the Earth in many ways.

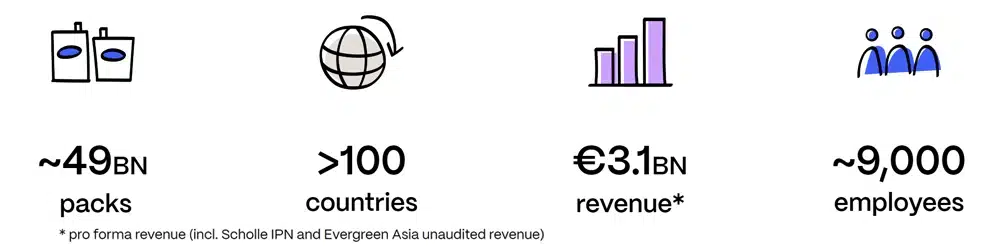

SIG by the numbers:

We’re With You From Idea to Execution

Solving big problems in unique ways is in our DNA. We do our best when we think holistically and come to market with a range of solutions that keep our environment in mind while making our customers’ lives easier.

Much like the packaging we manufacture, we are flexible in our ability to develop your ideal solution. Together, our technical sales team, packaging applications engineers, research and development team, and equipment engineers work to design a total packaging solution specifically suited to your product.

Packaging Applications Engineers

- Conduct applications assessments and develop tailored packaging specifications to best protect and deliver your product.

- Manage package validation process and protocols.

- Troubleshoot quality issues and production opportunities in your facility.

Equipment Engineers

- Design and build bag-in-box and pouch equipment to meet your unique packaging needs.

- Perform factory acceptance testing and site acceptance testing and in-depth training for your production staff.

- Field service maintenance available within hours of reported issues.

Research & Development

- Work with you and your end-users to develop packaging solutions.

- In-house materials labs available for quality and interface testing so that you can be sure your product and our package solution works from day one.

- Ongoing, dedicated support and analysis for any issue that may arise.

Technical Sales

- Highly-trained sales team ready to work with you to determine the best package solution tailored for your product’s needs.

- Coordinate customer interface with our Packaging Applications Engineers, Materials Lab, R&D Engineers, and Equipment Engineers to simplify your day.

Serving world-class brands

Our history is one of breakthrough packaging successes, replacing rigid alternatives and creating new markets for cartons, bag-in-box, and pouch packaging along the way. We help brands add: consumer convenience; new methods of serving and dispensing products; product safety enhancements; and time and economic savings. Each year, we safely and reliably deliver billions of servings of food and beverages around the world.