Fitments for flexible packaging

We strive to be the best total packaging solutions supplier, from development to production to service – and that includes our fitments. Our injection molding presses are engineered to provide you with an optimal fitment solution. From pilot molds to test new, custom designs to full production, we’re here to support you.

Our approach to fitments

Injection molding and assembly

SIG injection molds and assembles fitments designed to provide an ergonomic interaction with your product for all ages and abilities.

- Our fitments are designed with focus on optimized functionality and fit for sealing to various types of film.

- Our taps, connectors, and caps are designed to suit your needs –whether that’s on a retail shelf, a fast-paced restaurant operation, or industrial use.

Our vertical integration and global footprint ensures competitive pricing and supply contingencies. Our Industry 4.0 approach to manufacturing uses data, automation, and robotization. Together with clean room manufacturing and in-line inspection systems, we maintain high quality from design to production.

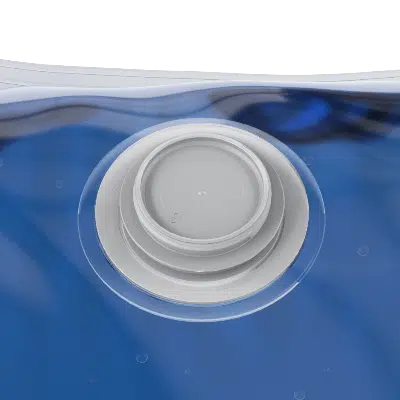

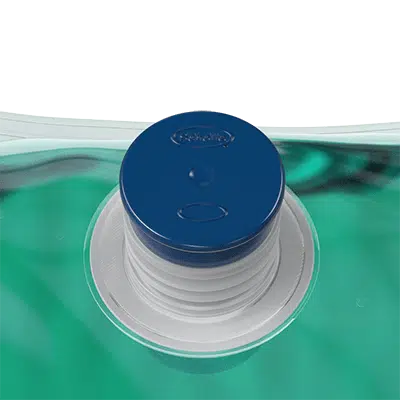

Caps and taps:

Ergonomic, easy-to-use solutions designed for people of all ages and abilities.

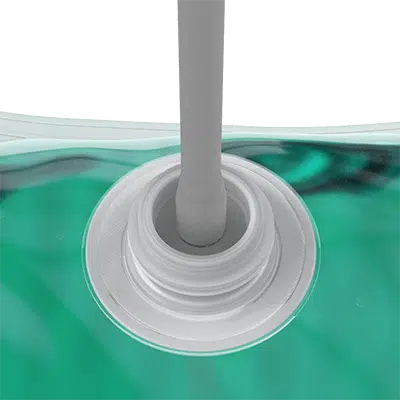

Connection systems:

Facilitate safe, precise dosing and mixing of liquid products from dispensers.

Environmentally-conscious:

Designs engineered to be lightweight and with the Earth’s limited resources in mind.

SIG fitments product line catalogue

Now you can download our entire fitments product line catalogue for bag-in-box and spouted pouch. This 64-page book covers our capabilities in development (and production of) leading fitment technology.

DownloadOur capabilities

We injection mold and assemble billions of fitments every year. Our clean room fitment manufacturing environments are built for quality and product safety.

Scale and precision:

- Molding capabilities from small trial presses to high-cavitation cells to fit your production needs.

- Leading-edge polymer use to maximize quality and recyclability.

- Fitment assembly capabilities feature “pop-on” and tethered cap innovations for environmental efficiencies.

- “No-touch,” robotic production lines with automated in-line quality inspection systems ensure the fitments are manufactured with highest reproducibility.

Our taps, connectors, caps are designed to suit your needs –whether that’s on a retail shelf, a fast-paced restaurant operation, or industrial use. And in all we do to design and manufacture fitments, the environment is a priority with solutions that are engineered to empower your own journey in the circular economy.

Ergonomics and environment:

- Taps built to extend opened shelf life.

- Fitments with automatic shut-off to eliminate chance of spills and waste.

- Single-piece fitments to eliminate loose plastic in the environment.

- Lightweight fitments to maximize functionality with minimal source material use.

Industry-leading injection molding

We strive to be the best total packaging solutions supplier, from development to production to service – and that includes our fitments. Our injection molding presses are engineered to provide you with an optimal fitment solution. From pilot molds to test new, custom designs to full production, we’re here to support you.

Our fitments are manufactured using:

- Clean room manufacturing to meet stringent food compliance standards.

- State-of-the-art hybrid and electric Husky molds to reduce energy consumption.

- Automated assembly machines to increase speed and efficiency.

- In-line inspection systems for closed-loop quality control throughout the manufacturing process.

- Industry 4.0 automations to reduce direct human interactions with the products.

Mold-making technology

We’re equipped to take your fitment concepts from idea to execution. Our fitments engineers work with you to tailor-make your optimal fitment solution. We work with our injection molding experts to design, produce, and test fitment molds starting with rapid prototyping and single-cavity pilot molds all the way to high-cavitation molds for commercial production.

Innovative design for the circular economy

Our products and processes are built to realize a significant reduction in the use of fossil materials and related CO2 footprint while providing a positive consumer experience. To that end, we strive to engineer products that meet one or more of the below tenets to ensure we are all moving forward in our sustainability journey.

What matters in our products

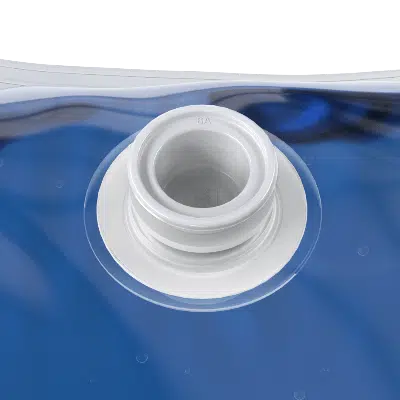

CleanSeal™

Leading-edge sealing technology using induction which enables the use of recyclable PP and PE film structures. Faster cycle times, lower energy requirements, and compact equipment footprint aid in reducing reliance on natural resources.

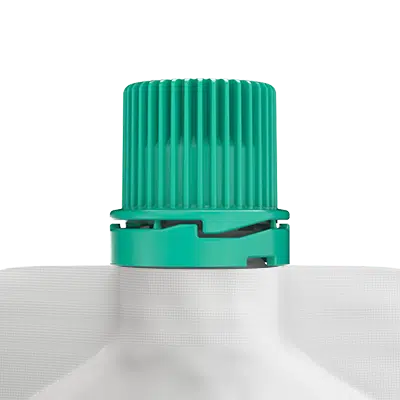

Tethered Caps

Ensuring closure components are recycled, not just recyclable.

SIG has developed a line of tethered caps for spouted pouches that comply with European regulations pushing towards single-piece fitment designs. Our tethered cap solutions eliminate loose components that might not be placed into the recycling stream, while offering child-safe designs and improved ergonomics. With these easy-to-reseal fitment solutions, spills and other opportunities to waste products are less likely.

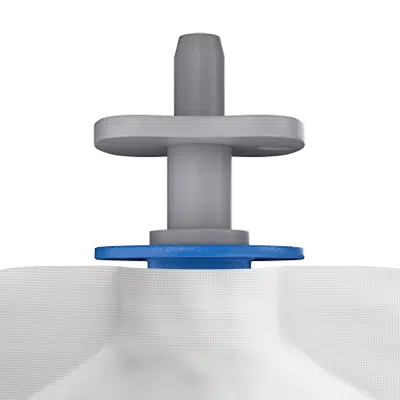

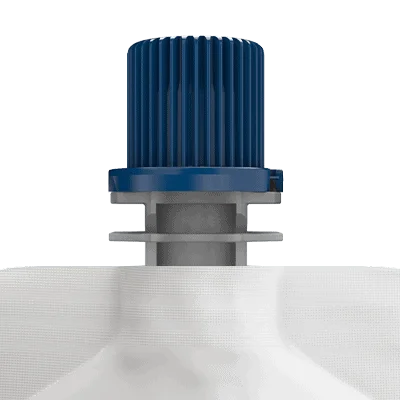

Snap-On

• Patented design offers a reduction in energy

required for manufacturing, assembly, and sealing

• Offers easy, twist-off use for consumers of all ages

• Toynorm compliant

• Dual-purpose tamper evidence also offers

tether for cap

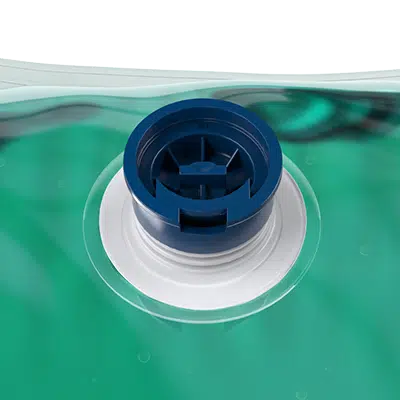

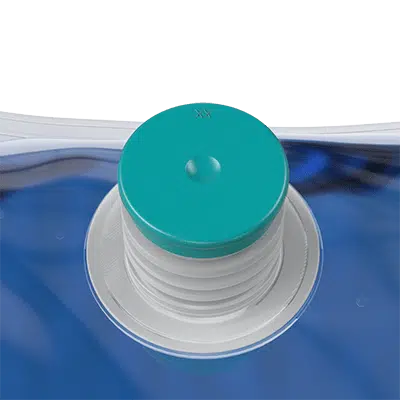

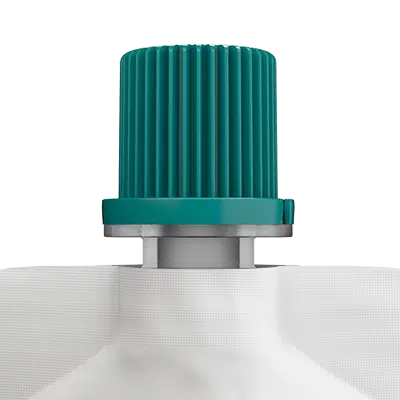

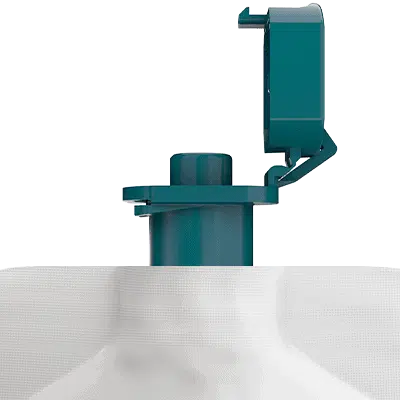

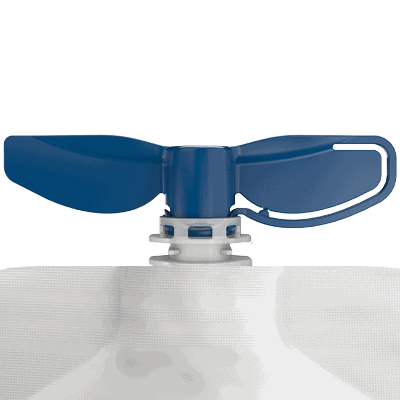

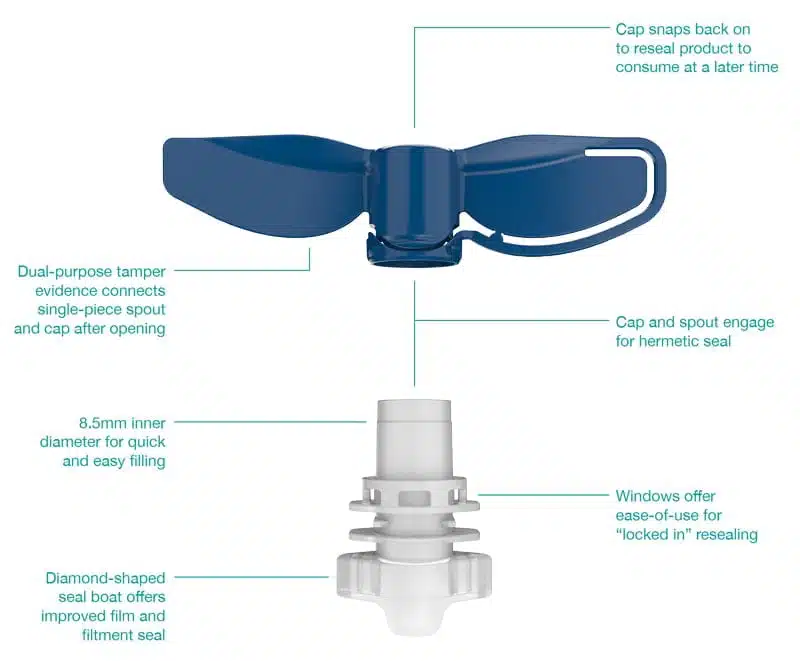

Flip-Top

• Ideal for HFFS applications

• Single-piece spout and cap offers integrated tamper evidence

• Flip-top functionality allows single-handed use

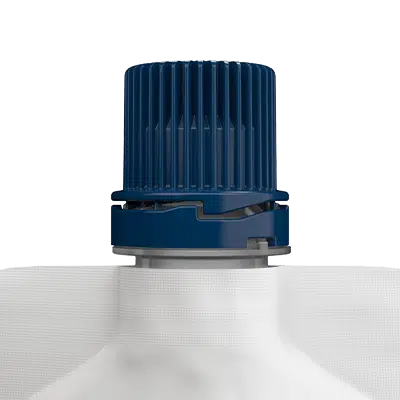

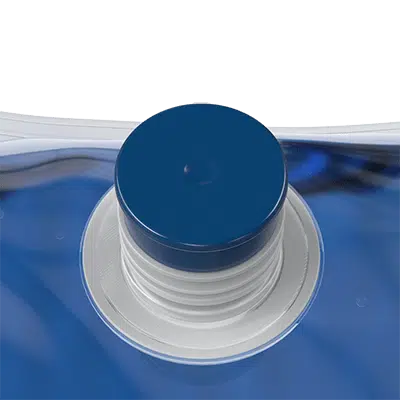

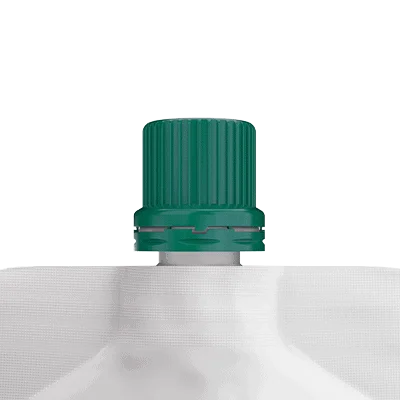

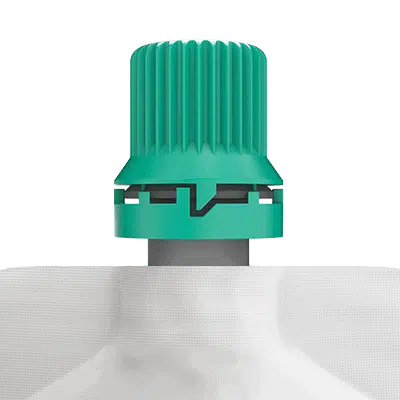

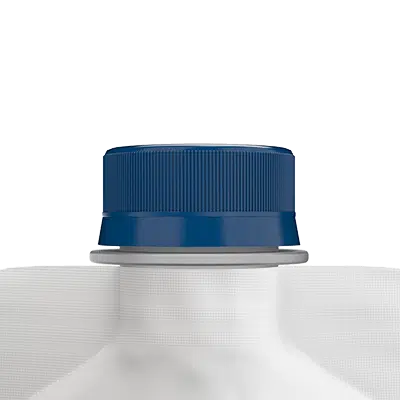

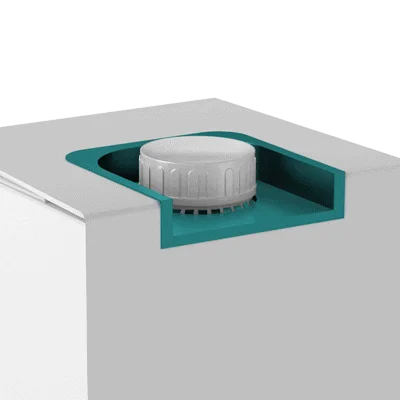

Screw-On

• Diamond seal boat offers improved interaction

between film and spout

• Tethered hinge keeps cap from blocking product flow

• Lightweight design reduces reliance on raw materials

Benefits and key features of snap-on fitments

Fully compatible with industry standards, these fitments have been engineered with the following tenets in mind:

Intuitive and ergonomic

We design our fitments to be accessible for people of all ages and abilities.

Lightweight

Engineered to use less material, creating less strain on Earth’s resources.

Molded-in bridge

Ready for sealing without needing additional step for tamper evidence.

Compliance

European regulations around single-piece fitments as well as Toynorm compliance.

Performance

Comparable benefits to non-tethered options.

Aseptic fitment expertise

In the 1970’s, SIG developed the aseptic filling machine which enabled the aseptic bag-in-box packaging process. Prior to SIG, the aseptic process had been limited in package type and was most commonly used for dairy products. Aseptic packaging for bulk bag-in-box allowed processors to provide out-of-season products throughout the year, revolutionizing the storage and transportation of processed fruit and vegetable products.

In recent years, we have seen a shift in consumer demands towards healthy beverage options, resulting in the growth of the aseptic drink category. SIG’s advancements in filling equipment and bag-in-box technology provide solutions for retail and institutional establishments who wish to offer coffee, dairy, juice, smoothies, and other functional beverages, while retaining nutritional value.

Our history

We pioneered aseptic packaging technology for both bag-in-box and spouted pouches, helping you offer the best-quality product while expanding the potential channels and locations available to you.

Expand potential

Aseptic technology allows you to offer preservativefree, shelf-stable products that stay fresh up to 12 months on the shelf with no refrigeration needed. Aseptic opens your potential for ecommerce, while extended shelf life helps drive higher consumption and use in expanded locations.

Hermetic sealing

The first part of aseptic package technology is a hermetically sealed package. To ensure the package is hermetically sealed, we use a “bubble” pressure test to verify that nothing comes into or out of the package. We follow the FDA Bacteriological Analytical Manual, specifically chapter 22C. To ensure that our package is hermetically sealed and capable of commercial sterility, we perform a micrbiological challenge test with Geobacillus stearothermophilus spores (GS1).