Our sustainability story

Because sustainability is a journey, and this is ours. It’s not an easy one, but we are determined to overcome challenges in our quest to develop net-positive packaging solutions.

Our sustainability commitments are an integral part of our business strategy, our Corporate Compass. They represent how we will give back more than we take. To have a net-positive impact on people and the planet. To create lasting change. Included in our strategy are industry-leading goals for each of the four positives: Climate+, Forest+, Resource+, and Food+.

Climate+

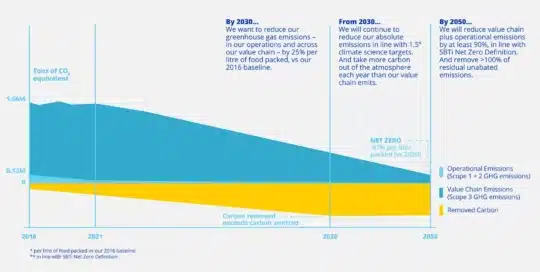

Our Climate Positive commitment is to reduce our greenhouse gas (GHG) emissions in line with 1.5° climate science, take more carbon from the atmosphere than our value chain emits, and pioneer carbon-negative packaging concepts.

Click for more

Food+

Our Food Positive commitment is to bring people even more safe and nutritious food and drink, wherever it is needed, at prices they can afford, and reduce the amount of food and drink that is lost during filling, storage, transport, and consumption.

Click for more

Resource+

Our Resource Positive commitment is to lead the way towards a fully circular packaging system. Our ambition for our packs is that one day, they are made exclusively from renewable or recycled materials, and that every pack we make gets recycled.

Click for more

Forest+

Our Forest Positive commitment is to maintain 100% of the forest area we source from through FSCTM certification for all the paperboard we procure to make our cartons, and support the creation, restoration, protection, or improved management of an additional 650,000 hectares of sustainable forest.

Click for moreCase studies in sustainability

Water packaging

Nearly 1.5 million plastic bottles are sold every minute throughout the world. Approximately 70% of these bottles end up in landfills where they take at least 450 years to completely degrade.

Scholle IPN has packaged water in bag-in-box all over the world for over 20 years. We’ve produced over 60 million 3-gallon bag-in-box packages, which replace production of 1.3 billion 16.9 oz (500 mL) water bottles.

Lightweight and recyclable pouches

Materne’s GoGo squeeZ brand is working to lower their reliance on resources and packaging has been a primary focus.

We’ve worked with Materne to develop a recycle-ready film structure for their pouches, and to significantly reduce their closure’s overall plastic weight.

Eliminating waste in automotive lubricant packaging

Shell Lubricants was striving to satisfy their customer’s need for the most sustainable and ergonomic package for motor oil in the industry.

Moreover, Shell also needed to respond to service operators’ call for an easier-to-use, faster, and more-economical package by changing their traditional, rigid 1-liter (1-quart) bottles to flexible bag-in-box packaging.

Pouch packaging for concentrated beverages

Coca-Cola’s Freestyle dispensing system was introduced in 2009. With a touchscreen-operated flavor selection interface, consumers can custom-make +100 drink flavor combinations.

The key to making this system work was to package super-concentrated flavorings in small pouches separately; then mix the flavors with bulk HFCS from bag-in-box packaging and carbonated water dispensed at the on-site location.