Flexible Packaging for Plant-Based Nutrition Products

Growth in Plant-Based Sector

Companies have been continuously thinking outside of the box when it comes to alternatives for dairy products, with many options for yogurt, ice cream, and coffee. With the popularity of plant-based foods and beverages at an all-time high, a company’s ability to package these products with their consumers’ interests in mind will make – or break – a brand’s retail success.

Consumers are more aware than ever of their environmental impact. They want their favorite brands to step up to the plate and offer packaging that allows them to purchase their favorite plant-based foods while also remaining environmentally conscious. In fact, according to Mintel, 64% of US food and beverage shoppers believe that manufacturers should be responsible for environmentally-friendly choices. Flexible packaging offers consumers a solution that incorporates these must-haves: a package that has the ability to house their go-to foods and beverages while also keeping the environment and product quality at the forefront of the brand’s values.

Flexible Packaging Benefits for Plant-Based Nutrition

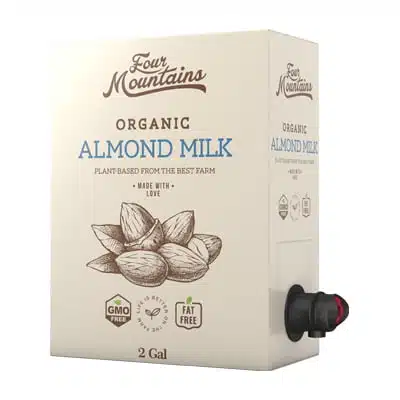

In order to support a flourishing product line, an innovative packaging solution capable of housing a diverse range of products is needed. Flexible packaging offers additional capacity as well as product and package differentiation. It affords the ability to package more viscous product types, which can aid in new product development—especially within the plant-based protein segment. With flexible packaging, you have differentiated packaging sizes ideal for direct-to-consumer home delivery. From sizes as small as two ounces to larger, multi-serve sizes, flexible packaging has you covered.

In order to support a flourishing product line, an innovative packaging solution capable of housing a diverse range of products is needed. Flexible packaging offers additional capacity as well as product and package differentiation. It affords the ability to package more viscous product types, which can aid in new product development—especially within the plant-based protein segment. With flexible packaging, you have differentiated packaging sizes ideal for direct-to-consumer home delivery. From sizes as small as two ounces to larger, multi-serve sizes, flexible packaging has you covered.

Plastic is good – waste is bad. Many flexible packaging options offer components that can be easily recycled and used again. For example, more coffee producers are moving away from just offering recyclable pods and bags to biodegradable and compostable alternatives to deliver more eco-friendly alternatives. Spouts, caps, and other fitments are molded with hard plastic, and films are created with mono-material structures in order to allow the entire package to be recycled. Due to the nature of flexible packaging, it offers improved evacuation and open shelf life as compared to rigid options, and uses less material, resulting in less product waste.

With aseptic flexible packaging, you can deliver your preservative-free food and beverage products without cold chain. In addition, flexible packaging fitments are created to maintain hermetic seals with the package, providing peace of mind that you are safely delivering the best quality product possible. With this opens new doors for flexible packaging to become the go-to option for the retail segment. More specifically, aseptic packaging allows consumers to have their plant-based products delivered safely and preservative-free following Amazon’s SIOC protocols, and with the quality they deserve. The ability for these natural products to be delivered with ease stems from eliminating cold chain transportation that dairy products typically require. As the online grocery market continues to flourish, consumers can comfortably order their favorite products without worrying whether they will receive the same quality as in-store purchasing.

Partners in Innovation

Recently, North Carolina Food Innovation Lab contacted us to install a lab-scale bag-in-box filler, the TrueFill® 900. Affiliated with North Carolina State University, this state-of-the-art food innovation lab specializes in plant-based foods and beverages, working with entrepreneurs for test markets for anything from helping develop new products to running formulas and co-packing.

Recently, North Carolina Food Innovation Lab contacted us to install a lab-scale bag-in-box filler, the TrueFill® 900. Affiliated with North Carolina State University, this state-of-the-art food innovation lab specializes in plant-based foods and beverages, working with entrepreneurs for test markets for anything from helping develop new products to running formulas and co-packing.

Currently, the lab is creating a new children’s food product. A key initiative with this is balancing nutritional needs with the desire for plant-based products. According to Bill Aimutis, Executive Director of the North Carolina Food Innovation Lab, they were interested in using flexible packaging because it offers many sustainability benefits including cutting down on the amount of packaging needed for a product, while offering size flexibility – something that is important to them as they work to help entrepreneurs scale up their recipes for full production.

Peter Messacar: Director, Business Development - Retail

If you're interested in chatting about anything above, feel free to drop me a line! We are partnered with scale-up innovation labs like North Carolina Food Innovation Lab to get you up and running.

Contact me