Introducing Corner-Spout Pouches: An Optimized and Versatile Flexible Packaging Solution

October 14, 2021

Flexible packaging has to be versatile. Our new line of corner-spout pouches delivers environmentally conscious benefits throughout the supply chain.

Scholle IPN has been a leader in flexible packaging for over seven decades. No matter what we’re working on, we always prioritize sustainability and source reduction—we want to deliver high-performing products that reduce waste and are responsibly made.

At this year’s Pack Expo, a leading industry trade show where companies display innovative packaging formats, we were thrilled to debut our new line of corner-spout pouches. Corner-spout pouches provide an improved product-to-package ratio and a better ergonomic experience while reducing product waste and energy emissions.

Combining Sustainability and Usability

Central to our work are engineered solutions that optimize the relationship between the product being packaged and the packaging itself. This is critical because many packaging solutions fail on three key sustainability factors:

- They require too much energy to make

- There’s simply too much packaging (both primary and tertiary)

- Consumers cannot use everything inside a package due to evacuation difficulty

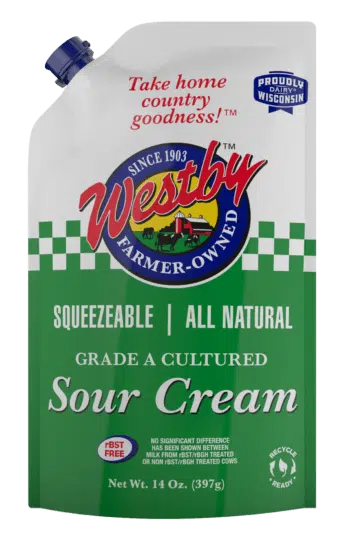

Think of the last time you ordered something online and the amount of packaging that came in the box. Or recall a time you were scraping the bottom of a container of sour cream or a jar of peanut butter to get every last bit. Every time there’s unnecessary packaging or leftover product that can’t be retrieved is a moment where waste is generated.

Our new line of spouted pouches solves these common problems. “We’re excited to offer this format—especially now—as brand owners commit to a more sustainable world,” says Monte Kimball, Director of Retail Business Development for Scholle IPN. “This is a great fit for what we do best: provide innovative materials (including fitments) for packaging liquids.”

Environmentally Responsible From Beginning To End

Spouted pouches provide measured sustainability gains throughout their lifecycle. They can be used for a variety of products and are suitable replacements for glass, PET bottles, and aluminum cans. By switching to spouted pouches, we observed reduced waste during manufacture, shipping, and end use:

REDUCED ENVIRONMENTAL IMPACT: Spouted pouches require less material to make. Compared to a 1-quart bottle, a 1-quart spouted pouch uses 68% less material by weight, processes 53% fewer greenhouse gases, and produces 68% less post-consumer waste.

IMPROVED PRODUCT-TO-PACKAGE RATIOS: Our spouted pouches are lightweight – especially compared to the products they contain and comparably-sized rigid packages. A greater product-to-package ratio means a lot of things, including lower manufacturing costs, more efficiency during shipping and distribution, and increased value for consumers.

REDUCED PRODUCT WASTE: Most packaging solutions are difficult to empty completely. We’ve all experienced having to scoop out the last of an item or shake a bottle to get what’s stuck to the bottom. Corner-spout pouches ensure maximum evacuation—you can get everything out of the packing easily and without making a mess.

IMPROVED ERGONOMICS: Corner-spout pouches are designed for users of all ages. Flexible packaging means that the pouches are easy to grab and hold onto, and the fitments are simple to open and close.

Our corner-spout pouches can also come with an integrated air handle, which allows the pouch to sit proudly on a retail shelf. The air handle is also optimal for consumers, who can simply grab the side to pour out of the spout.

Available For All Your Needs

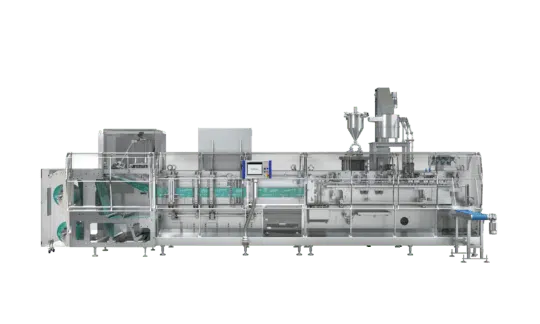

Our new corner-spout pouches are available both pre-made and in rollstock for horizontal form-fill-seal (HFFS) machines.

Pre-made pouches come in 500ml, 750ml, and 1000ml (1 liter) sizes and are made with Scholle IPN’s highly engineered barrier films. We paired our pre-made pouches with our LinkCap™, a tethered fitment that is EU compliant and reduces waste both on our end (during manufacturing) and for consumers (because the fitment is tethered, it’s much more likely to be recycled).

Pre-made pouches come in 500ml, 750ml, and 1000ml (1 liter) sizes and are made with Scholle IPN’s highly engineered barrier films. We paired our pre-made pouches with our LinkCap™, a tethered fitment that is EU compliant and reduces waste both on our end (during manufacturing) and for consumers (because the fitment is tethered, it’s much more likely to be recycled).

With our pre-made corner-spout pouches, we aimed to give companies freedom by making the pouches highly adaptable—that means you can use them for almost anything, in a variety of formats and sizes, and with a range of fillers. “Our pre-made pouch offering is versatile. We can provide customers a fully assembled and sealed pouch designed to be filled through the spout, a fully assembled pouch able to be filled through the top, or a pouch and spout  separately for filling through the top and then inserting the spout following the filling process,” he says.

separately for filling through the top and then inserting the spout following the filling process,” he says.

We recently acquired Bossar, a leading manufacturer of horizontal form-fill-seal equipment, making Scholle IPN a one-stop shop for all your filling needs. The Bossar BCF line is specifically designed to fill pre-made, corner-spout pouches. We also have filling machines that can meet our customers where they’re at—if you’re slowly entering the field and just starting out with a new product or have an established brand and high-volume capabilities, we have a machine for you.

We can also help design corner-spout pouches for clients with HFFS fillers. “Customers can select a filler from a number of Bossar models, such as the BMS 1.6 machine. Scholle IPN will provide the same proven films as we do for premade pouches,” Kimball shares. We also offer a wider range of tethered fitments, including FlipCap™, a simple one-piece tethered flip-top, ideal for products with higher viscosities.

We can also help design corner-spout pouches for clients with HFFS fillers. “Customers can select a filler from a number of Bossar models, such as the BMS 1.6 machine. Scholle IPN will provide the same proven films as we do for premade pouches,” Kimball shares. We also offer a wider range of tethered fitments, including FlipCap™, a simple one-piece tethered flip-top, ideal for products with higher viscosities.

Building a More Circular Economy

Sustainability is not just about making environmentally-friendly products. Rather, it’s an approach we use to think carefully about the products we make and how they’ll be used. We try not to design one-off solutions or products that tackle just one problem. Instead, we find value in innovations that can be widely applied and contribute to a more circular economy.

Corner-spout pouches are a simple, environmentally responsible packaging format that provides sustainability gains throughout its lifecycle. “We believe that corner-spout pouches offer brands a format to move towards a more circular economy because of their structure, compatibility with tethered fitments, and significantly better package-to-product ratio than most formats out on the market,” Kimball says.

Kimball sees the potential in corner-spout pouches in a number of fields, like—but not limited to—personal care and beauty items, household products and cleaners, auto lubricants, food items like condiments and broths, and RTD drinks and coffee creamers.

If you’re considering a corner-spout pouch, come talk to us. We can help you find a total packaging solution that’s perfect for you—regardless of what product you make.