SIG TrueFill 21

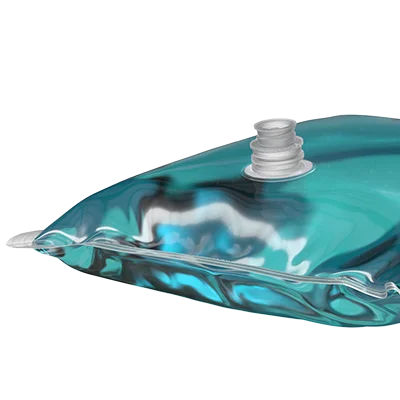

Get into bag-in-box packaging today with this simple, semi-automatic filler supported by Scholle IPN engineers.

- Fresh-fill capable

- Manual filler requiring one operator

- Fills packages up to 6gal

Product Specifications

Key Features

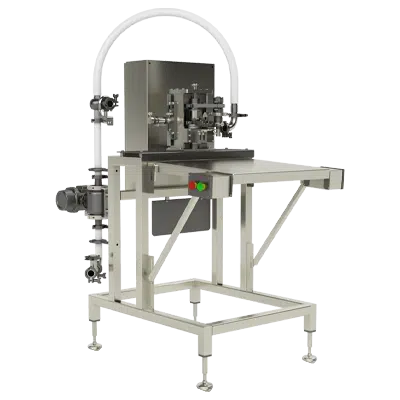

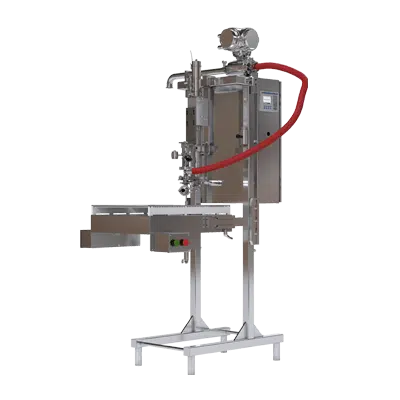

The Scholle IPN TrueFill® 21 Fresh filling machine is a single head, semi-automatic filler that requires one operator. The filler is constructed of non-corrosive material and all product contact surfaces are 316L stainless steel and food-grade construction.

Known Process Applications

Ambient

Occurs when a product is filled into a package with no additional sterilization treatment.

Filling Method

Common Package Sizes

Typical Markets

Maintenance

Clean-in-place (CIP) machine cycles are applicable. CIP cycle controlled by filler programming, works in line with your existing CIP system to complete the CIP circuit. This is a customer-dependent processes and can be initiated from the CIP screen. Our expert equipment field service technicians can support and maintain this filler for your continued success.

Bag Size and Speed

| Package Size | Filling Speed | |

|---|---|---|

| (L) | (Liters per Minute) | (Bags per Minute) |

| 3.7 (1.0) | 227 (60) | 8 |

| 11.3 (3.0) | 227 (60) | 6 |

| 19.0 (5.0) | 227 (60) | 5 |

| 22.7 (6.0) | 227 (60) | 4 |

Equipment Specifications

| Filling stations | 1 |

| Machine dimensions (L x W x H) | 1346mm x 1067mm x 1854mm (53in x 42in x 73in) |

| Air Consumption | 90-140 PSI, 5CFM (dry/oil free) |

| Electrical Data | Power (Single Phase): 110VAC, 2Amps, 60Hz |