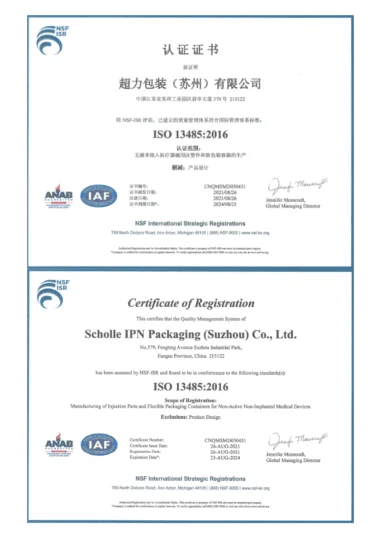

China Plant Receives Prestigious ISO 13485 Certification

Our plant in Suzhou, China was recognized for its commitment to safety by the International Organization for Standardization by earning ISO 13485 certification.

Scholle IPN is thrilled to announce that our plant in Suzhou, China, received ISO 13485 certification. This certification, whose rules were determined by the International Organization for Standardization (ISO) and then conferred by a third party, recognizes the Suzhou plant for going above and beyond in their quality management systems for manufacturing injection molding parts and flexible packaging for non-active and non-implanted medical devices.

Scholle IPN is thrilled to announce that our plant in Suzhou, China, received ISO 13485 certification. This certification, whose rules were determined by the International Organization for Standardization (ISO) and then conferred by a third party, recognizes the Suzhou plant for going above and beyond in their quality management systems for manufacturing injection molding parts and flexible packaging for non-active and non-implanted medical devices.

We pride ourselves on innovative designs and cutting-edge technology, but that means nothing if we don’t have the systems in place to make sure things are made safely and responsibly. Third-party certifications, like the ISO 13485 certification,help us hold ourselves to the highest standards of operation.

A Choice to go the Extra Mile

According to the ISO website, “certification ISO 13485 is not a requirement of the standard.” Rather, this certification represents standards above and beyond what is required, which is a valuable way for us to test our internal protocols. While we value creating our own measures of success, we take advantage of certification programs like this to test ourselves and make sure we’re abiding by current best practices. We do this at all our Scholle IPN locations, including our plants in Brazil and Chile, who recently received their FSSC 22000 certification for food safety for the eighth and third year in a row, respectively.

“This certification is an internationally-recognized standard of quality and safety,” says Amy Song, Scholle IPN Product Manager based in Suzhou. “It’s a way for others to recognize us as a trustworthy manufacturer. This certificate allows our products to be used in entirely new markets, like the medical supply industry.”

This year’s ISO 13485 certification, referred to as ISO 13485:2016, “is designed to respond to the latest quality management system practices, including changes in technology and regulatory requirements and expectations,” the ISO website explains. “The new version has a greater emphasis on risk management and risk-based decision making, as well as changes related to the increased regulatory requirements for organizations in the supply chain.”

The ISO 13485 certification is not an evaluation of a product, but rather the quality management systems (QMS) and safety protocols in place as a product is made. To receive this certification, an audit must be done by an approved third-party entity. An auditor is looking for a number of things, including:

- Knowledge and promotion of regulations either from governing bodies, which we did through location-wide World Class Manufacturing (WCM) assessments and trainings

- Evidence or documentation of quality control systems

- Systems to mitigate and manage risk

- Traceability on products used during manufacture

- Self-maintained systems to measure and encourage internal improvement

Safety Matters

A product is only as good as the sum of its parts. That’s why the ISO 13485 certification focuses on systems and protocols rather than the final product. This certification is a way for us to communicate to our partners that we care about how their packaging solutions are made. “Obtaining the ISO 13485 certificate increases customer satisfaction and builds credibility,” says Song. “Our customers can be confident in the products we make and know we are committed to quality management.” This certification speaks to our bigger goal of providing flexible packaging solutions in a responsible way.

Scholle IPN has always looked beyond what’s in front of us. Our products are used in a variety of industries, from food safety to agricultural chemicals to pharmaceuticals, and that requires us to stay on top of leading trends across different areas of expertise.

That’s why we welcome frequent audits and seek out certifications—we’re not simply a flexible packaging company leading in one particular industry, but rather a company that aims to produce the best-of-the-best total packaging solutions across industries. Learn more about what Scholle IPN can do to meet your flexible packaging needs.