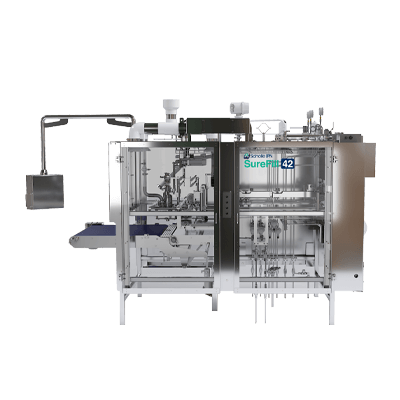

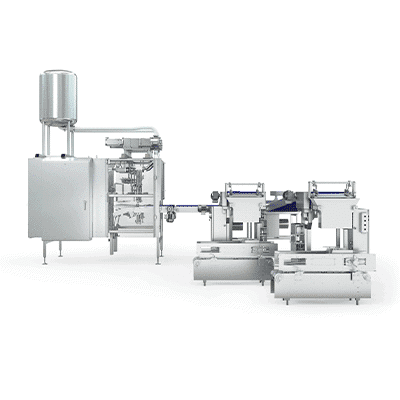

SIG SureFill 42 Aseptic

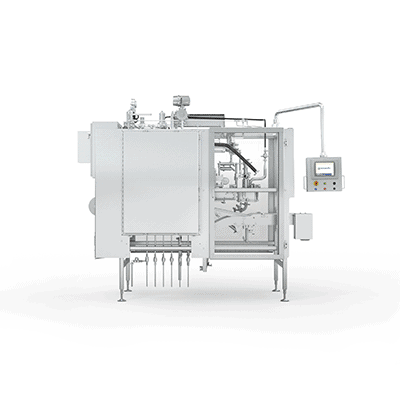

Advanced bag-in-box filling technology that delivers versatility for Fresh, High-Acid, Low-Acid, and Ultra-Clean (ESL) processors.

- Aseptic-capable

- Automatic, web-fed filler

- Fills packages up to 30L

Product Specifications

Key Features

Advanced bag-in-box filling technology that delivers versatility for Fresh, High-Acid Aseptic, Low-Acid Aseptic, and ESL processors. The SureFill 42 allows you to fill single-fitment bags, both with and without a hose, greater than 21 liters (5.5 gallons).

Known Process Applications

Ambient

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-Clean (ESL)

Uses UV, laminar flow, and/or hydrogen peroxide to achieve high sterility levels for short shelf-life products.

Aseptic

Fills commercially-sterilized products into pre-sterilized packaging. Products can be held unopened without refrigeration.

Filling Method

Common Package Sizes

Typical Markets

Maintenance

Clean-in-place (CIP) and sterilize-in-place (SIP) machine cycles are applicable. CIP cycle controlled by filler programming, works in line with your existing CIP system to complete the CIP circuit. Both are customer-dependent processes and can be initiated from the CIP/SIP screens. Our expert equipment field service technicians can support and maintain this filler for your continued success.

Bag Size and Speed

| Package Size | Filling Speed | |

|---|---|---|

| (L) | (Liters per Minute) | (Bags per Minute) |

| 3.0 (0.8) | 227 (60) | 13-15 |

| 4.0 (1.0) | 227 (60) | 12-14 |

| 5.0 (1.3) | 227 (60) | 11-13 |

| 10.0 (2.6) | 227 (60) | 9-10 |

| 20.0 (5.3) | 227 (60) | 6-7 |

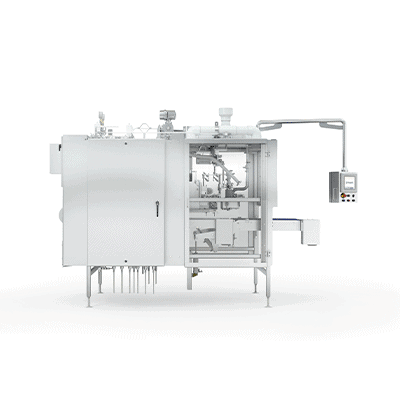

Equipment Specifications

| Filling stations | 1 |

| Machine dimensions (L x W x H) | 2630mm x 3333.2mm x 2155mm (103.5in x 131.5in x 84.84in) |

| Air Consumption | 90-140 PSI, 40CFM (dry/oil free) |

| Electrical Data | Power (3-Phase): 240VAC, 80Amps, 60Hz |

| PLC | Allen Bradley and Panelview - Series |

Footprint

Height: 2630mm (103.5in)

Length: 3333.2mm (131.5in)

Width: (2155mm (84.84in)

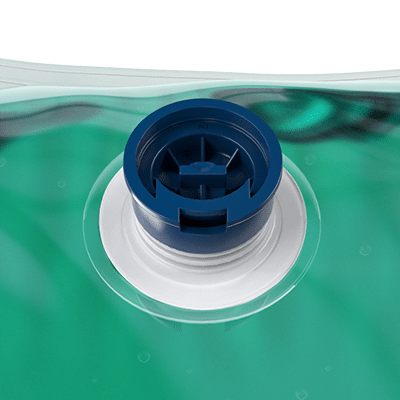

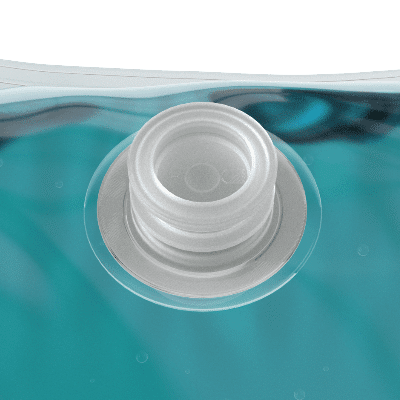

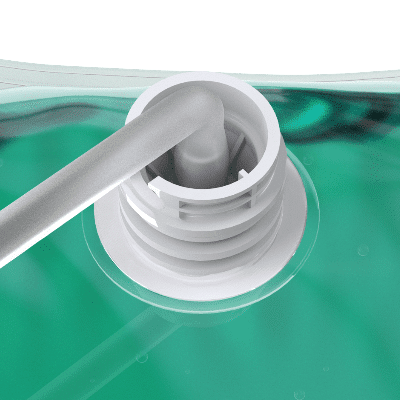

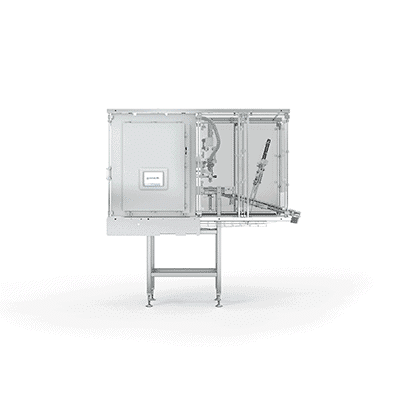

In-Feed, Vapor Sterilization Tunnel, and Filling

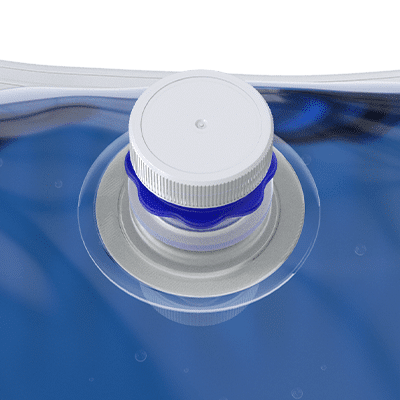

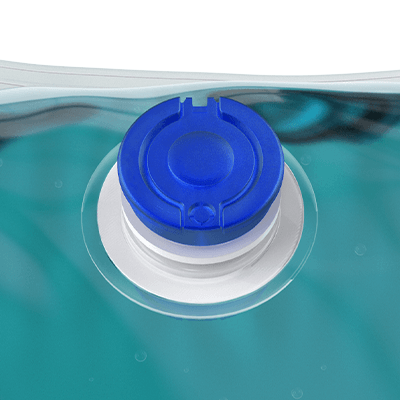

- What’s Happening in the Tunnel? The sterilization tunnel connects to the vapor sterilization tunnel (VSTTM) unit to deliver vaporized hydrogen peroxide which sterilizes the outside of every spout and fitment before they enter the filling head area.

- Why the Tunnel is Important. Maintains the sterility of the package’s spout and fitment so that aseptically-processed liquids can be filled into the bag-in-box package. To increase overall system efficiency, multiple packages are shuttled into VST at once.

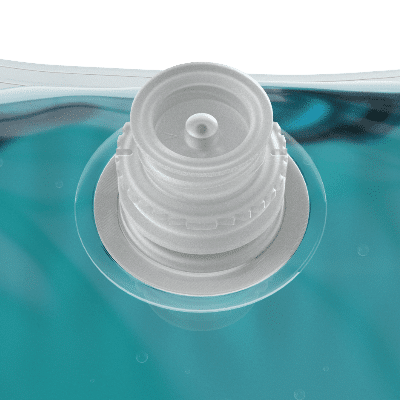

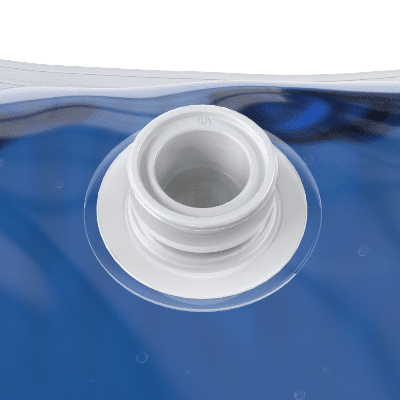

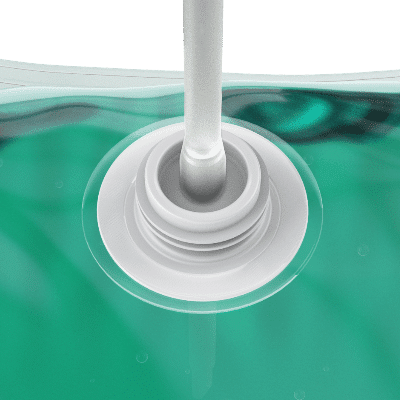

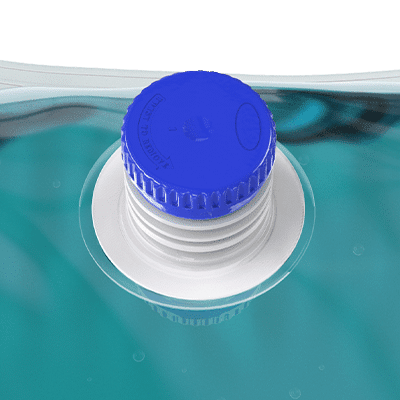

- How Does the Fill Head Work? The spout and fitment are loaded into jaws. An airless fill pad rises to help reduce the amount of air and foaming in the package during fill. The fitment is removed and the fill head lowers to fill the bag. Filling is measured by an integrated flow meter. The fitment is replaced with a hermetic seal to maintain aseptic stability.