Film and laminates

Our knowledgeable engineers work with customers to successfully design unique and valuable film solutions for any market. We strive to delight demanding end users through innovative technology and consistent delivery of reliable barrier films.

Our approach to film and laminates

Designed for Protection

We extrude, laminate, and deliver printed barrier film designed to meet your product specifications. Our wide range of solutions includes everything from one- to nine-layer films, as well as recyclable, monomaterial structures.

- Our films are designed with focus on optimized functionality and fit for sealing to fitments.

- Our films are manufactured to protect your product and withstand the rigors of difficult supply chains.

- Our vertical integration and global footprint ensure competitive pricing and supply contingencies.

- Our Industry 4.0 approach to manufacturing uses data, automation, and robotization wherever possible.

Mono-Material:

We focus on design for the circular economy. Producing monomaterial film enables the finished packaging to be more-easily recycled and thus, have value after their initial lifespan.

Fit-For-Purpose:

Heavy, rigid packaging formats require more energy to produce, transport, and store. Because flexible packaging has the capability of being downgauged to an ideal, lightweight film structure, the resulting environmental scores can be optimized.

Environmentally-Conscious:

Flexible film—and the packaging it helps create—often has less process and delivery waste than most rigid containers. The resulting greenhouse gas emissions are often favorable for flexible.

Our capabilities

Extrusion and lamination

We have extensive experience developing unique film blends which provide the ultimate protection and package performance for a diverse range of flowable products. From time-sensitive, fresh foods and beverages, to aggressive chemicals and sensitive pH products, our flexible packaging solutions are designed to protect your product and keep it safe from fill through final dispensing. We offer:

- Recyclable film solutions that enable you on your journey towards a more circular economy.

- Barrier protection designed to keep your product safe and extend secondary shelf life.

- Solutions that fit seamlessly where you need them, whether in retail, institutional, or industrial applications.

SIG film product line catalogue

Now you can download our entire film product line catalogue. This 52-page book covers our capabilities in development (and production of) leading flexible film technology.

DownloadFilm design for the circular future

Protection

Barrier film and flex-crack resistance technology, combined with our leading dispensing systems, provides maximum protection for both the product and end user.

Sealability

Our film range includes products which can fit your equipment’s preferred sealing method. From heat, to ultra-sonic, to next-generation, energy-efficient methods.

Recyclable

Whenever possible, our films are designed to have simple, mono-material construction to aid in recyclability of finished packaging.

Recyclable film technology

Printing options

We surface-print films using a solvent-free ink.

Solventless lamination

Eliminating solvents from the lamination process eliminates related greenhouse gas emissions.

Co-extruded films

By eliminating lamination from some of our structures, we use less energy and chemicals during film production. These structures are simpler, aiding in recyclability.

Lightweight structures

By using fewer base materials, we can save raw materials throughout the supply chain.

Eliminate aluminum

Barrier technology in plastics has progressed to a point where we no longer need to incorporate environmentally-costly metals.

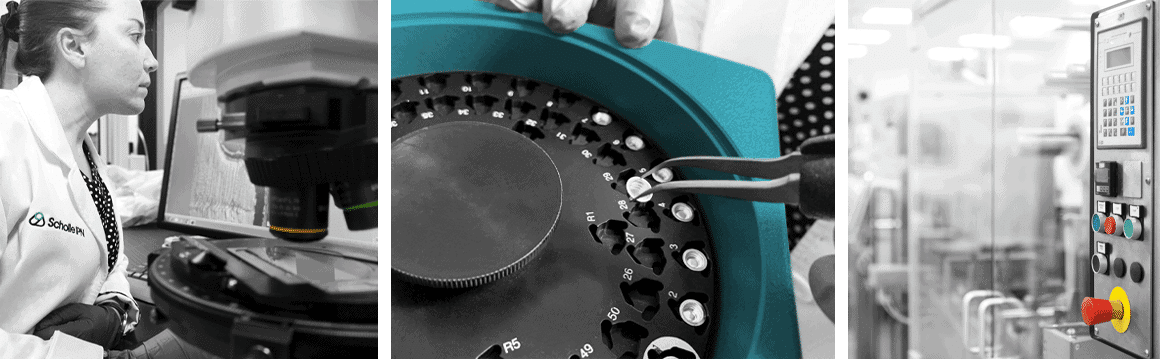

Materials science and development for film

We strive to be the best total flexible packaging solutions supplier, from development to production to service. We apply a scientific approach to all our R&D processes to offer innovative packaging solutions that fit your unique requirements.

Our extensive experience developing unique film blends provides protection and performance for a diverse range of products from dairy to battery acid. And, with globally-placed production capabilities and localized expertise, we can ensure your film solution is made with leading technology and quality.

The key to this expertise lies in our Materials Science Laboratory and partnerships with leading universities and innovation firms.

Learn more about our Materials Science Lab.