Wine Packaging

Flexible bag-in-box and pouch packaging provides eco-conscious solutions that keep wine safe from fill through end-use, and extend freshness after opening.

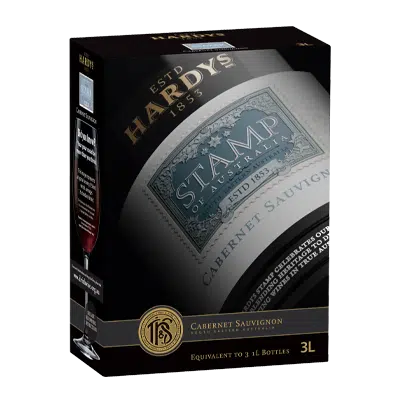

Bag-in-Box for Wine

Tap into market trends by offering your wine in a clean, eco-conscious alternative to traditional wine bottles. Bag-in-box protects your wine and eliminates many quality control problems like cork taint, “lightstruck” flavor damage, and breakage in transit. Our innovative bag-in-box systems include film, fitments, and filling equipment for a total flexible packaging solution engineered to protect your wine from fill through final dispensing. We provide:

- Longer shelf life once opened, with superior product evacuation.

- Closed-loop systems that keep air out and protect your product.

- Versatility to deliver your wine anywhere you need.

- Solutions that minimize your environmental impact and leave less packaging waste behind.

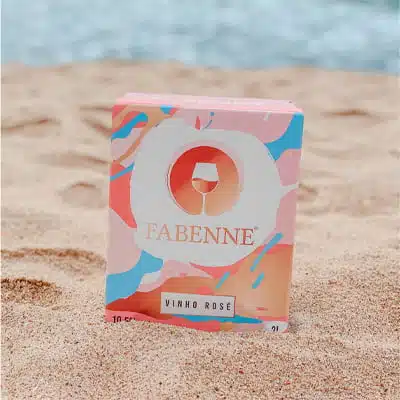

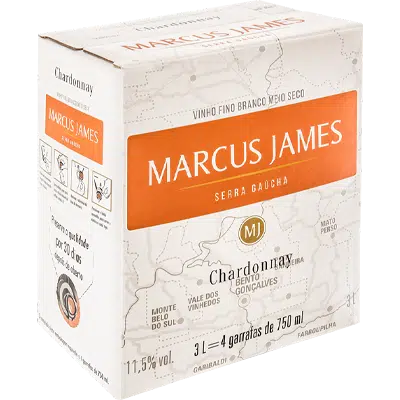

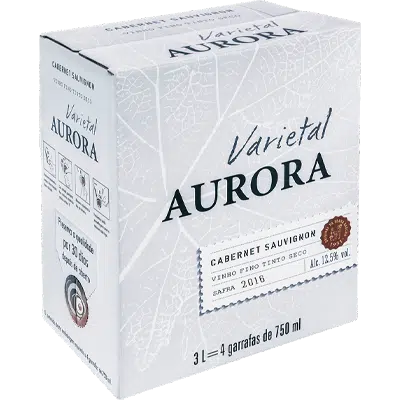

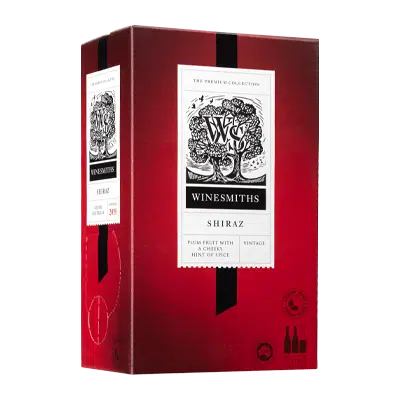

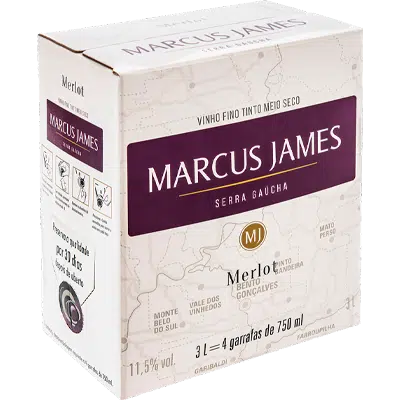

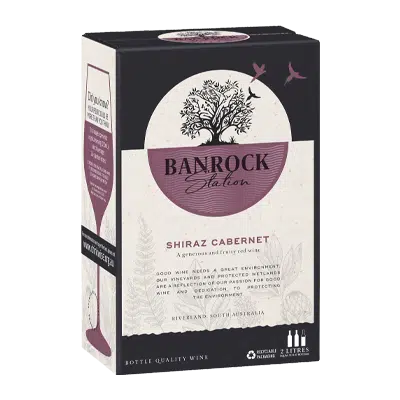

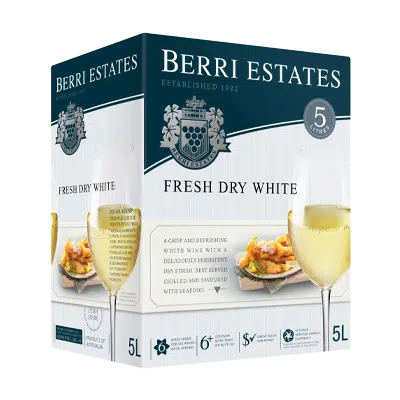

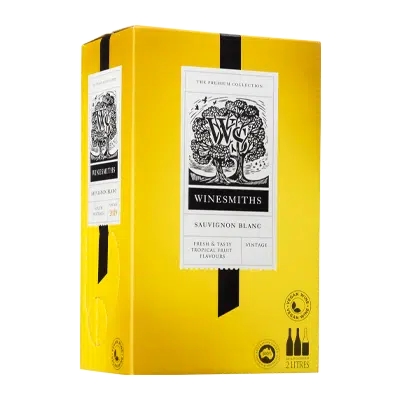

Retail Bag-in-Box for Wine

Stand out in crowded retail aisles by offering wine in environmentally responsible, multi-serve packaging with benefits like:

- Extended freshness and longer shelf life.

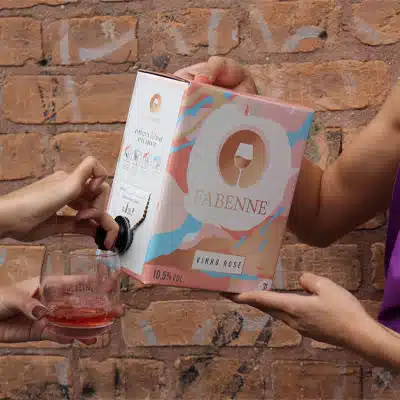

- Ergonomic, on-tap dispensing.

- Ability to dispense nearly every last drop inside.

- Bulk packaging that’s still portable.

Institutional Bag-in-Box for Wine

Eliminate waste from partially consumed bottles, and use our innovative bag-in-box systems to offer wine by the glass at high-volume retailers like stadiums, concert venues, and amusement parks. Secure, closed-loop systems keep air out, extending freshness once opened by up to four weeks. Our bag-in-box products provide:

- Compact, secure, shatterproof packaging.

- Easy-to-use, ergonomic, push-button interface.

- Superior evacuation to maximize profits and minimize waste.

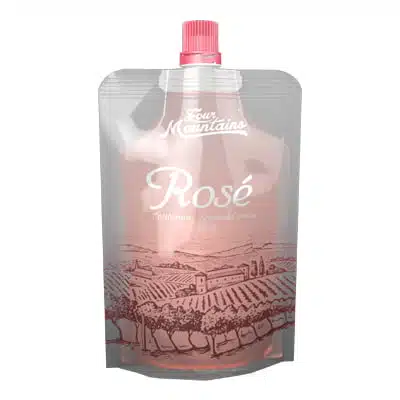

Pouch Packaging for Wine

Expand your market by using this highly-convenient package format to offer retail consumers a range of options, including: portable wine pouches for camping and picnicking; resealable multi-serve wine pouches; and trial-size pouches that enable sampling. Their lightweight, compact design leaves far less waste behind than bulky glass bottles, making them perfect for offering wine in vending settings and places like cruise ships and airlines.

- Compact, lightweight, and shatterproof.

- Clean usage in a package that’s easy to “get it all out.”

- Typically lower carbon footprint than heavy rigid alternatives.

- Optimized product-to-package ratio, leaving less waste volume.

Pre-Made Pouches for Wine

Our CleanPouch® system helps you streamline your operation by focusing on your product while relying on us to deliver quality pouch packaging. These pre-made spouted pouches are delivered on rail systems, so it’s easy to get your filling operation up and running.

Benefits of CleanPouch® System:

- Various film options including clear for visibility of volume.

- Customizable fitment options for spouts and caps that fit your needs.

- Dynamic filling equipment for startup through full-scale, automated operations.

Pouch Solutions for Wine

If you’re interested in getting started or are already producing pouches using horizontal form-fill-seal (HFFS), count on us for high-quality materials needed for making your pouches:

- Films: Choose from our wide range of options from traditional foil to consumer-preferred transparent. Plus, our RecShield™ pouch film can be recycled with other polyethylene films.

- Fitments: Select from our wide variety of unique and innovative pouch spouts and caps engineered for the rigors of HFFS production.

- Equipment: Use our combined pouch fitments and barrier films in tandem with the top-of-the-line Bossar BMS 4.2 for a complete HFFS pouch packaging solution.