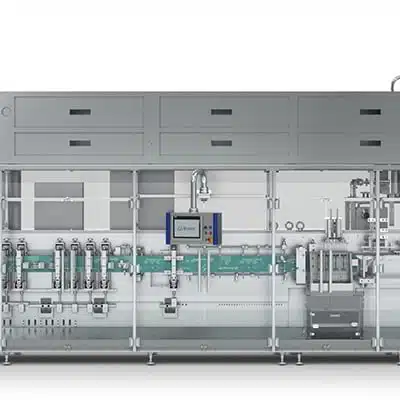

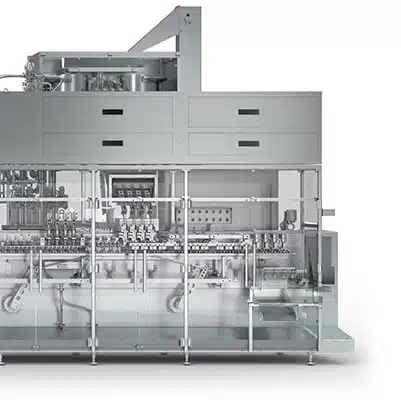

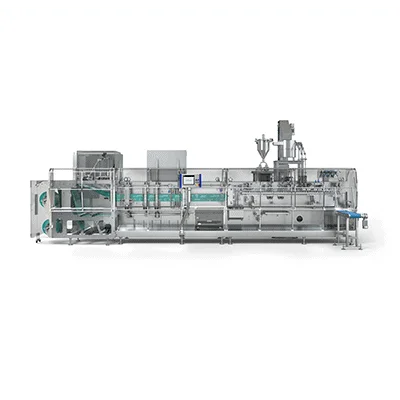

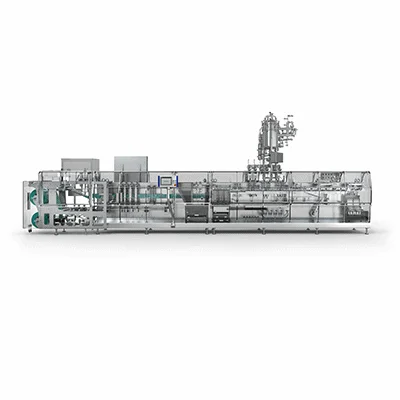

SIG Motion 240 Servo 4.2

This horizontal form-fill-seal (HFFS) machine works in duplex and quadruplex, forming and filling up to 240 pouches per minute.

- Full servo motion allows independent operation between stations

- Walking beam transport system offers precision from forming to sealing

- Mirroring capabilities to increase operational ease

Product Specifications

Key Features

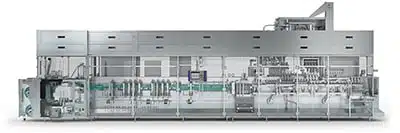

The Bossar BMS 4.2 uses state-of-the-art technology and is servo-controlled. The multiple-axis movements are independently controlled by a transmission system patented by Bossar. This machine is intelligent, reliable, easy to operate, and requires little maintenance. It offers:

- Better accessibility for easier maintenance.

- A 3D touchscreen.

- Pouch width automatic correction system.

- An instruction manual, as well as electronic and pneumatic diagrams, available on the touchscreen.

- Up to 10% productivity increase over typical mechanical HFFS machines.

- Less maintenance due to the fact that there are less wearing parts.

- Pouch seal quality comparable to pre-made pouches.

- Sanitary construction.

- Energy efficiency with excess power being sent back to the grid.

- The latest technology with optical fibers, optical barriers, position sensors, vision cameras, and more.

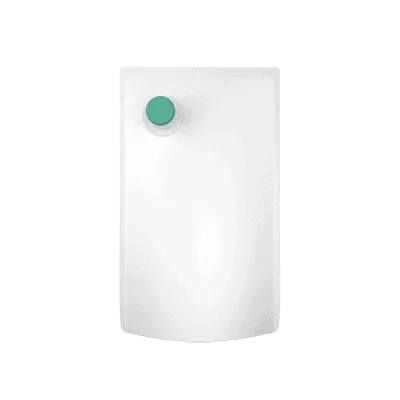

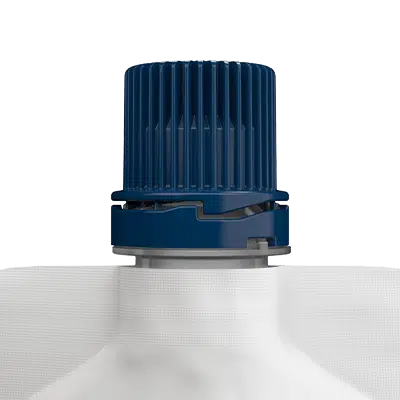

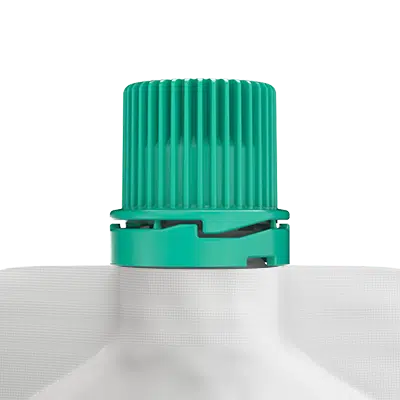

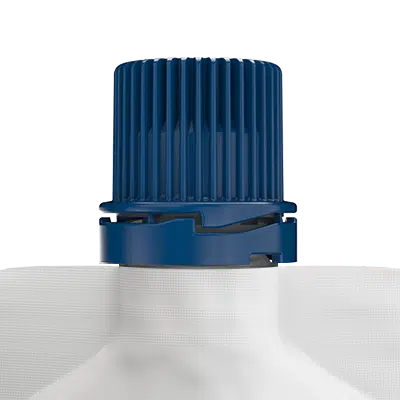

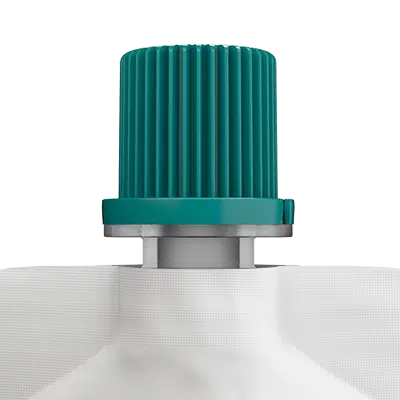

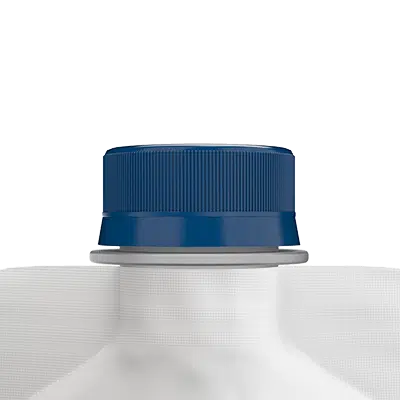

The Bossar BMS 4.2 offers a number of shapes, styles, and designs for increased product differentiation on the rank. This machine works well with our barrier films and highly-engineered fitments.

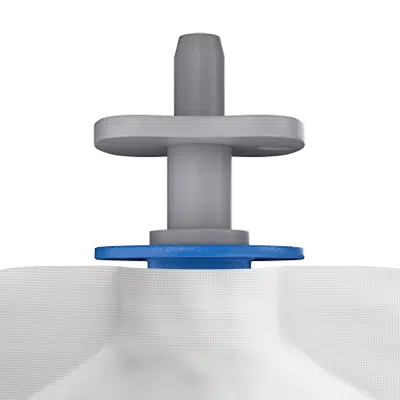

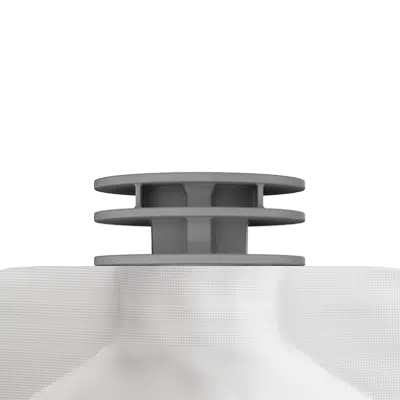

Zippers and spouts can be inserted for product preservation and ease-of-use.

Known Process Applications

Hot-Fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Ambient

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-Clean (ESL)

Uses UV, laminar flow, and/or hydrogen peroxide to achieve high sterility levels for short shelf-life products.

Filling Method

Common Package Sizes

200mL to 1600 milliliters (6.7 fl oz to 54.1 fl oz)

Typical Markets

Maintenance

Clean-in-place (CIP) and sterilize-in-place (SIP) machine cycles are applicable. CIP cycle controlled by filler programming, typically with valve to complete CIP circuit. Both are customer-dependent processes and can be initiated from the CIP screen. Our expert equipment field service technicians can support and maintain this filler for your continued success.

Pouch Size and Speed

| Pouch Style | Format Range (mm) WxH | Maximum Volume | Filling Speed | |||

|---|---|---|---|---|---|---|

| Minimum | Gusset | Maximum | Gusset | (c.c.) | (Pouches per minute) | |

| FLT-2 | 120 x 120 | n/a | 210 x 300 | n/a | 1150 | 130 |

| FLT-4 | 80 x 120 | n/a | 100 x 300 | n/a | 350 | 240 |

| STU-2 | 120 x 120 | 40 | 210 x 300 | 50 | 1600 | 130 |

| STU-4 | 80 x 120 | 25 | 100 x 300 | 32 | 475 | 240 |

Equipment Specifications

| Transport System | Servo-motorized grippers |

| Reel Diameter | 600mm (23.6in) |

| Reel Width | 600mm (23.6in) |

| Reel Core | 70mm to 76 mm (2.8in to 3in) |

| Filling stations | Up to 3 |

| Electrical Consumption | 20 kW |

| Air Consumption | 800L/min (211.3gal/min) |

| Electrical Data | 200-480V / 50-60 Hz / N + G / 3Ph (others under request) |

| PLC | ALLEN BRADLEY / SIEMENS (others under request) |

| Noise Level | <70 dB |

| Safety | CE & UL Standards |

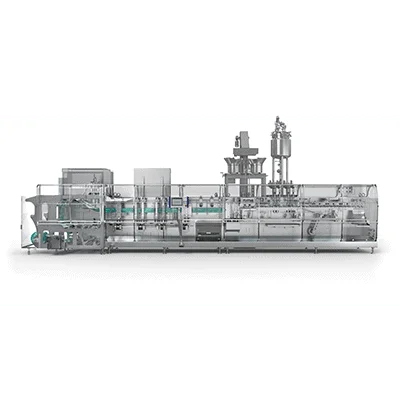

Check out the Bossar BMS 4.2 in action!

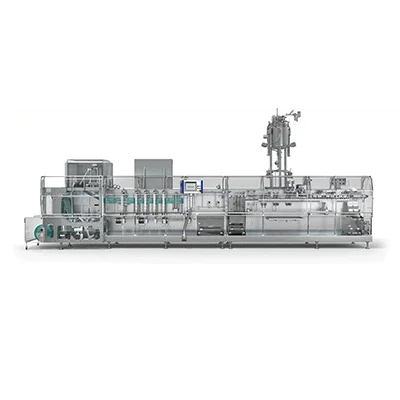

The SIG Motion 240 Servo 4.2 is an integral part of the Danonino pouch operation. If offers flexibility in shapes, products, and flavors.

SIG offers a wide range of top-of-the-line horizontal form-fill-seal (HFFS) machines. Over the years, we have gained an excellent reputation for being an innovation driven company, introducing technological advances in the market, which have set new standards in HFFS manufacturing. Learn more at www.bossar.com.