Smoothie Packaging

Bag-in-box and pouch packaging provide eco-conscious solutions that keep smoothies safe and fresh from fill through end-use. With aseptic technology, products are shelf-stable and preservative-free—no refrigeration needed.

Bag-in-Box for Smoothies

Fast and safe delivery is as essential to a great smoothie as the fresh ingredients you put in it. Our aseptic packaging extends shelf life and makes it possible to deliver natural, fresh-blended smoothies without preservatives. Trust our innovative bag-in-box systems—including a wide range of film, fitments, and filling equipment—for a total packaging solution engineered to protect your smoothies from fill through final dispensing. We provide:

- Aseptic packaging technology to eliminate costly cold chain logistics.

- Versatility to deliver your yogurt anywhere you need.

- Solutions that minimize your environmental impact and leave less packaging waste behind.

- Reduced food waste with longer secondary shelf life and maximum product evacuation.

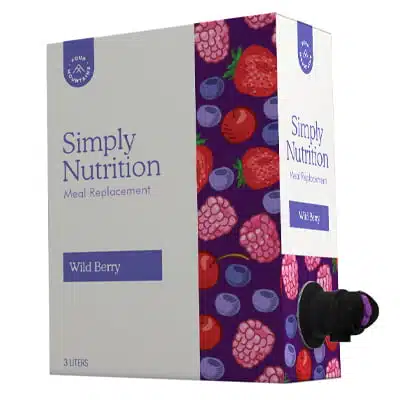

Retail Bag-in-Box for Smoothies

Stand out in crowded retail aisles by offering fruit- and yogurt-based smoothies in unique, multi-serve packaging with benefits like:

- Easy storage and smaller packaging footprint.

- On-tap dispensing from refrigerators.

- Improved ergonomics and accessibility for people of all ages and abilities.

- Extended freshness and longer shelf life with aseptic packaging technology.

Institutional Bag-in-Box for Smoothies

Safely and quickly dispense smoothies with our aseptic-capable, closed-loop systems that minimize opportunities for contamination while in-use and extend freshness upon opening. Our bag-in-box products are designed with fast-paced, foodservice operations in mind with:

- Simple hoses and quick-connect systems for reliable, consistent dispensing.

- Ability to fill and dispense low- or high-acid products from a single-fitment package.

- Easy disconnection with less mess for dispenser cleaning protocols.

- Improved evacuation to maximize profits and minimize waste.

Pouch Packaging for Smoothies

Utilize this highly-convenient, popular, and portable packaging format to offer your consumers single-servings of smoothies and other high-protein drink products. Encourage sampling of new flavors and offer trial pouches of products that are packaged in more traditional formats.

- Clean, straw-free usage in a package that’s easy to “get it all out.”

- Aseptic pouches are shelf-stable, no refrigeration required.

- Typically lower carbon footprint than heavy rigid alternatives.

- Better product-to-package ratio than rigid formats like glass jars and metal cans.

Pre-Made Pouches for Smoothies

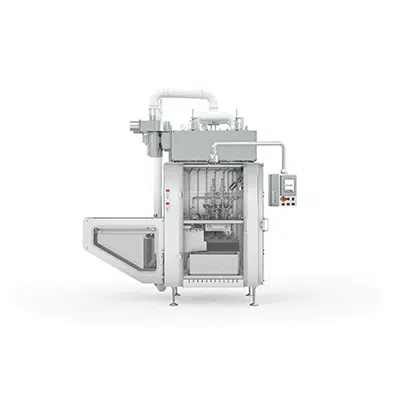

Our CleanPouch® system helps you streamline your operation by focusing on your product while relying on us to deliver quality pouch packaging. These pre-made spouted pouches are delivered on rail systems, so it’s easy to get your filling operation up and running.

Benefits of the CleanPouch® System:

- Optimal nutrient retention, flavors, and textures with CleanPouch® Aseptic.

- Customizable fitment options for spouts and caps that fit your needs.

- Dynamic filling equipment for small and full-scale, automated operations.

Pouch Solutions for Smoothies

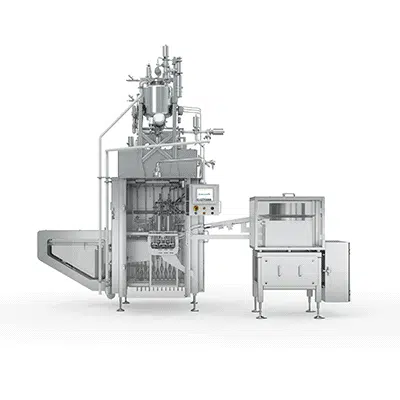

If you’re already producing pouches using horizontal form-fill-seal (HFFS), count on us for the high-quality materials needed for making your pouches:

- Films: Choose from our wide range of options from traditional foil to consumer-preferred transparent. Plus, our RecShield™ pouch film can be recycled with other polyethylene films.

- Fitments: Select from our wide variety of unique and innovative pouch spouts and caps engineered for the rigors of HFFS production.

- Equipment: Use our combined pouch fitments and barrier films in tandem with the top-of-the-line Bossar BMS 4.2 for a complete HFFS pouch packaging solution.