Pumpkin Packaging

Flexible bag-in-box and pouch packaging provide eco-conscious solutions that keep your pumpkin products safe and fresh from fill through end-use. With aseptic technology, products are shelf-stable and preservative-free—no refrigeration needed.

Bag-in-Box for Pumpkin

With aseptic packaging, you can deliver a fresh, natural product—no “cooked” flavors or preservatives—with extended shelf life and no refrigeration required. Our innovative bag-in-box systems include a wide range of film, fitments, and filling equipment for a total flexible packaging solution engineered to protect your products from fill through end-use. We provide:

- Aseptic technology to eliminate costly cold chain logistics.

- Versatility to deliver your pumpkin products anywhere you need.

- Solutions that minimize your environmental impact and leave less packaging waste behind.

- Reduced food waste with longer secondary shelf life and maximum product evacuation.

Institutional Bag-in-Box for Pumpkin

Safely dispense pumpkin products like particulates and purées with our aseptic-capable, closed-loop systems that minimize opportunities for contamination while in-use and extend freshness upon opening. Our bag-in-box products are designed with fast-paced, foodservice operations in mind with:

- Easy storage and smaller packaging footprint.

- Improved evacuation to maximize profits and minimize waste.

Industrial Bag-in-Box for Pumpkin

Use our industrial-sized flexible IBCs, tote liners, and drum liners to safely transport your pumpkin products and ingredients in packaging that offers cost savings throughout the supply chain. Our flexible industrial packaging facilitates:

- Clean and safe delivery of pumpkin to and from your production facility.

- Streamlining, demanding less resources to clean and service bulk containers.

- Eliminated reliance on cold chain due to ability to fill, store, and unload aseptically.

Pouch Packaging for Pumpkin

With aseptic technology, you can offer pumpkin products in perfectly portioned packaging that requires no preservatives or refrigeration. Our spouted pouches are available in sizes as small as 50 ml, up to larger, multi-serve sizes. Offer single servings or trial sizes to encourage sampling, or pouches of pumpkin for meal prep and baking kits.

- Ship smarter with ecommerce-ready flexible pouches.

- Aseptic pouches are shelf-stable, no refrigeration required.

- Typically lower carbon footprint than heavy rigid alternatives.

- Optimized product-to-package ratio, leaving less waste volume.

Pre-Made Pouches for Pumpkin

Our CleanPouch® system helps you streamline your operation by focusing on your product while relying on us to deliver quality pouch packaging. These pre-made spouted pouches are delivered on rail systems, so it’s easy to get your filling operation up and running.

Benefits of CleanPouch® System:

- Optimal nutrient retention, flavors, and textures with CleanPouch® Aseptic.

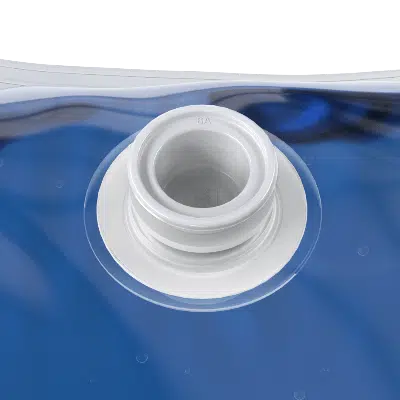

- Customizable fitment options for spouts and caps that fit your needs.

- Dynamic filling equipment for startup through full-scale, automated operations.

Pouch Solutions for Pumpkin

If you’re already producing pouches using horizontal form-fill-seal (HFFS), count on us for high-quality materials needed for making your pouches:

- Films: Choose from our wide range of options from traditional foil to consumer-preferred transparent. Plus, our RecShield™ pouch film can be recycled with other polyethylene films.

- Fitments: Select from our wide variety of unique and innovative pouch spouts and caps engineered for the rigors of HFFS production.

- Equipment: Use our combined pouch fitments and barrier films in tandem with the top-of-the-line Bossar BMS 4.2 for a complete HFFS pouch packaging solution.

Frequently Asked Questions

Why Choose Flexible Packaging for Pumpkin

Fruits & Vegetables Applications

Citrus Fruit

Deciduous Fruit