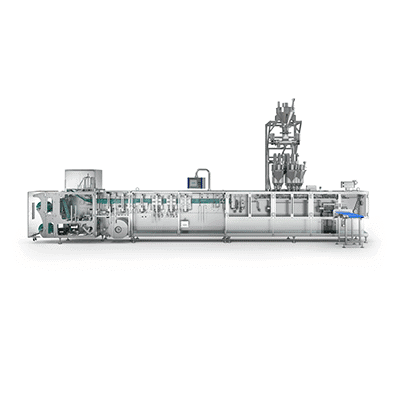

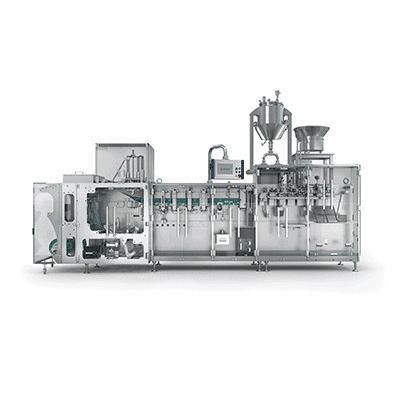

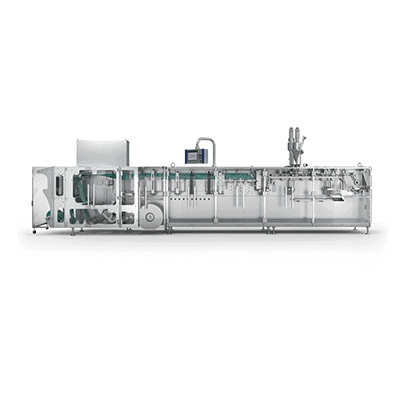

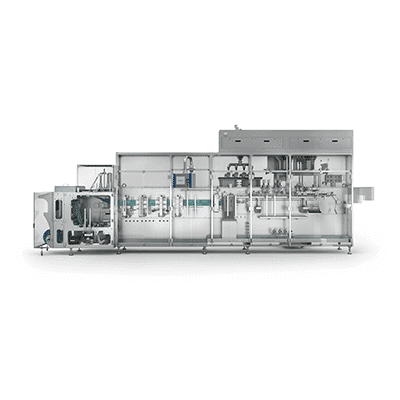

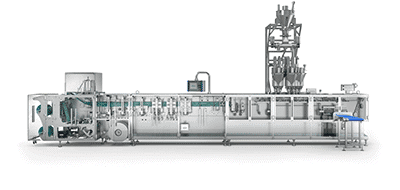

SIG Motion 120 Mech 3.3

The SIG Motion 120 Mech 3.3 forms, fills, and seals pouches within a range from 80mm x 80mm to 260mm x 300mm. It can reach an output of up to 120 pouches per minute and fill up to 2500 cc of product in simplex and 1200 cc in duplex.

- Features dosing units for various types of liquids

- Boasts individually temperature controlled sealing jaws

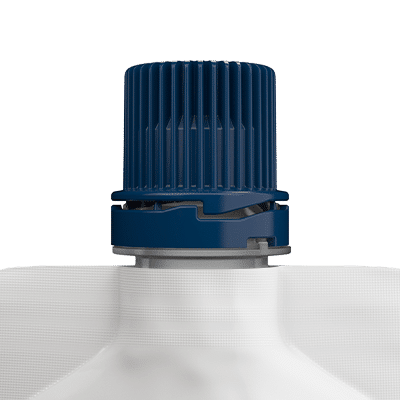

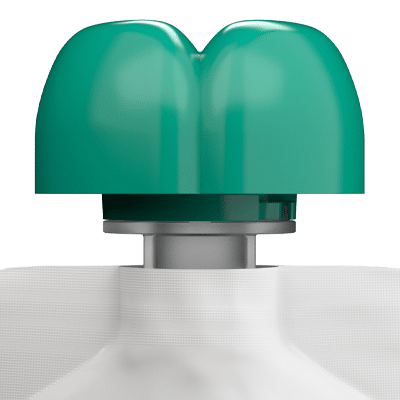

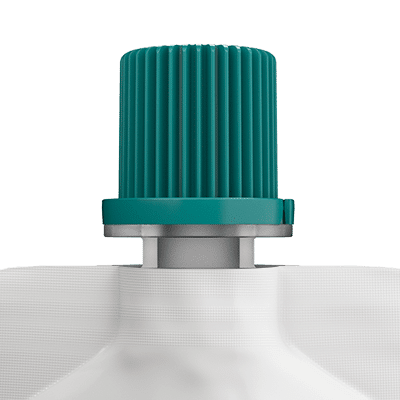

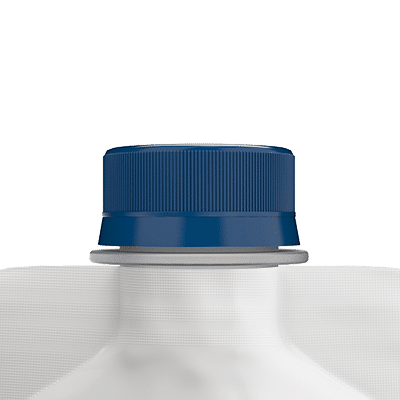

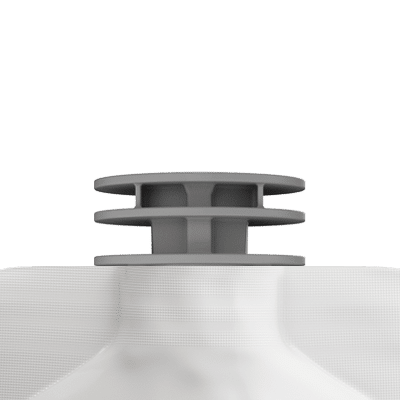

- Easily adapted to any type of fitment

Product Specifications

Key Features

The SIG Motion 120 Mech 3.3 is based on the modular frame construction composed of three independent modules:

- Unwind module

- Pouch forming module

- Filling module

SIG Motion 120 Mech 3.3 Benefits

- After evaluating the product characteristics and the application, our engineering department recommends the most suitable dosing unit.

- The Motion 120 Mech 3.3 machines are equipped with two filling stations that enable the filling of more than one product into the same pouch.

- These machines are equipped for the insertion of straws, spouts or zippers in

the pouches.

Known Process Applications

Hot-Fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Ambient

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-Clean (ESL)

Uses UV, laminar flow, and/or hydrogen peroxide to achieve high sterility levels for short shelf-life products.

Filling Method

Horizontal Form-Fill-Seal

Common Package Sizes

75mm x 80mm to 135mm x 135mm (3in x 3.1in to 5.3in x 5.3in)

850mL to 1100mL (28.7 fl oz to 37.2 fl oz)

850mL to 1100mL (28.7 fl oz to 37.2 fl oz)

Typical Markets

Agricultural Chemicals

Alcoholic Beverages

Automotive Fluids

Baby & Toddler Food

Beauty & Personal Care

Cleaning Chemicals

Coatings

Coffee & Tea

Condiments & Sauces

Dairy

Edible Oil

Frozen Beverages

Fruit & Vegetables

Functional Drinks

Juice

Nutraceuticals

Pet Food

Pharmaceuticals

Smoothies

Soft Drinks

Soup

Spreads & Toppings

Water

Pouch Size and Speed

| Pouch Style | Format Range (mm) WxH | Maximum Volume | Filling Speed | |||

|---|---|---|---|---|---|---|

| Minimum | Gusset | Maximum | Gusset | (c.c.) | (Pouches per minute) | |

| FLT-1 | 135 x 135 | n/a | 200 x 300 | n/a | 1050 | 60 |

| FLT-2 | 75 x 80 | n/a | 165 x 300 | n/a | 850 | 120 |

| STU-1 | 135 x 135 | 40 | 200 x 300 | 48 | 1500 | 60 |

| STU-2 | 75 x 80 | 20 | 165 x 300 | 48 | 1100 | 120 |

Equipment Specifications

| Transport System | Walking beam |

| Reel Diameter | 600mm (23.6in) |

| Reel Width | 750mm (29.5in) |

| Reel Core | 76mm to 152mm (3in to 6in) |

| Filling stations | Up to 3 |

| Machine dimensions (L x W x H) | 9000mm x 1580mm x 2220mm (354.3in x 62.2in x 87.4in) |

| Electrical Consumption | 15 kW |

| Air Consumption | 300L/min (79.2gal/min) |

| Electrical Data | 200-480V / 50-60 Hz / N + G / 3Ph (others under request) |

| PLC | ALLEN BRADLEY / SIEMENS (others under request) |

| Noise Level | <70 dB |

| Safety | CE Standards, OSHA |

Footprint

9000mm x 1580mm x 2220mm (354.3in x 62.2in x 87.4in)